The design of the local area often includes work on the arrangement of a decorative and at the same time physically resistant floor. The most advantageous coating is a terrace laid out with special boards. Other materials may be used, but the wood texture and environmental safety make this type of flooring an optimal solution. Due to the specifics of the use of such sites, technologists have developed appropriate rules by which a terrace board is installed. Do-it-yourself styling requires serious preparation of the place of registration and compliance with the nuances of installation. Do not forget that the terrace is a street surface, which is why it is affected by both atmospheric precipitation and mechanical stress from shoes when walking.

Benefits of Using Wood

Stone, porcelain stoneware and clinker are considered to be the best finishes in terms of protection against mechanical damage. Wood traditionally wins due to its unique texture and texture, as well as ease of processing.

However, modern impregnations and protective compounds make it possible to bring the tree closer to solid-state coatings and in terms of physical resistance. In addition, the technology of laying a terrace board itself involves the use of special rocks that are resistant to abrasion and deformation. In addition, there are special models of boards in which a corrugated surface is provided. The presence of longitudinal grooves, in particular, provides free flow of water. As a result, the terrace dries faster, eliminating harmful processes under the influence of moisture.

Decking

In the classical sense, terrace boards are a natural material made from solid wood. But in recent years, more and more often, special composite analogues called decking have been used for such tasks, through which no less high-quality laying of the terrace board is performed. Larch also does not lose its relevance, but in terms of practicality and ease of installation, artificial substitutes still win against it. As a rule, these are hollow boards made of sawdust and polymer composite mixtures. Decking is durable, unpretentious in maintenance, resistant to abrasion and makes it easy to dismantle the laid coating.

In addition to strength advantages, decking functionality can also be distinguished. In modern models, the same grooves for a spillway and a rough surface are provided. The photo below laying the terrace board also allows you to verify the ease of installation.

Which boards to use?

The choice of wood or decking is justified, but when buying, there are other criteria for selecting the board itself, its design features and size. First of all, the presence of an anti-slip coating is taken into account . This, again, is a corrugated board, which has a special top layer and is marked with the letter R. In terms of size, the choice depends on the laying area and the base on which the terrace board will be laid.

Laying methods vary and may include fixing on a concrete base, soil, concrete products slab, etc. A standard is considered to be a material 3 cm thick, about 5 m long and 15 cm wide. In this case, one should not expect that excessive thickness is sure to be good. The minimum limit is 2 cm, and with correctly laid lags this will be enough. An increase in thickness can lead to a large difference in levels relative to other coatings, which will necessitate additional termination of transitions and thresholds.

Wall preparation

The main preparatory works relate to the base, but the walls adjacent to the coating should also be prepared accordingly. Since during the rain spray from the terrace can wet the base, it must be protected. To do this, at a height of 20 cm from the ground, the wall is formed with a moisture-resistant lining. It is recommended that the material also matches the texture that the terrace board is endowed with. Do-it-yourself styling is done taking into account expansion joints, which are filled with elastic materials, silicone grouts and sealants. It is necessary to seal the upper edges of the base. This is also done with acrylic or silicone sealants.

Foundation preparation

Compliance with technology involves laying on a flat base. The board is very capricious in harsh operating conditions, so a reliable platform will be a good guarantee of durability. Depending on the scale of laying, one of two ways of creating the foundation can be chosen - a carefully tamped coating of gravel, rubble and a supporting frame or a full concrete pillow.

If you select a layout scheme for a terrace board in which there is no reinforced concrete slab, then excavation of unstable soil should be performed. After that, a layer of mineral concrete or gravel is poured and compacted by vibration. Then a bed of gravel and sand is poured up to a height of 5 cm. But to ensure maximum reliability of the terrace, it is still worthwhile to provide point supports in the form of concrete slabs. The size of the elements can be as follows: 30 cm in length and width, as well as 4 cm in height.

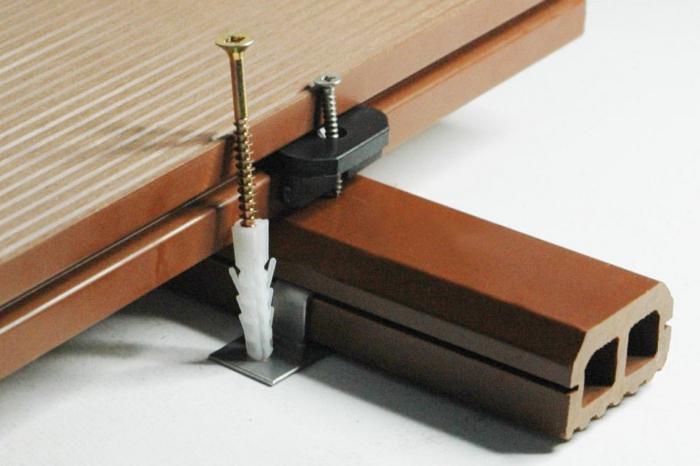

Lag laying

Installation lags in the terrace coating system serve as a substrate, linking point concrete supports and directly the boards. Their fixation is provided by dowels and stainless steel screws. Since the rules for laying a terrace board require a flat surface of the base, there must be a countersunk head in the fasteners. Logs are drilled in the center, after which the screw head is drowned in a niche formed. To fasten the logs to the concrete slab, dowel nails with a standard size of 0.8 x 8 cm are used. The joints between the logs can be implemented in two ways:

- due to the displacement of the elements between each other at a distance of 15 cm;

- joint-to-joint technique, maintaining a clearance of at least 3 cm.

There are also gaps between the logs and fixed surfaces in the form of walls and borders. This gap is also not less than 3 cm. If the logs are installed perpendicular to the direction of the drain, then small gaps should be left during installation. They are arranged on the principle of steps to facilitate the flow of water.

Decking

Boards must be nailed to the lags, observing an interval of 1 cm. Gaps must be left for free "work" of the tree. Thus, a more reliable and durable laying of the terrace board is performed. The instruction provides that the slots will allow the board to dry better and swell freely when in contact with rain water without deformation. For fastening, you can use stainless screws, brass screws, and in some cases an adhesive joint is allowed . There is also a method of lower mounting, in which traces of external fixation are not visible. But for this it is necessary to use plastic lags that do not absorb moisture. As a rule, these are special sets designed for the device of the terrace.

Expansion joints

When working with wood, expansion joints are especially important since their failure can lead to the formation of bends and cracks. This is especially important if you are laying a terrace larch board. The instruction in this case provides for filling the seams with edge tape or polystyrene foam. Termination is performed vertically, with filling the joints of the wall and the board. When calculating the filling height, it is important to take into account that the gap can compensate for temperature deformation, not only for the tree itself, but also for the concrete slab.

The standard size of the seam in width is 1.5 cm. They also serve as dividers of the coating into rectangles or squares. In this case, the frequency of the arrangement of the gaps should vary in the range of 2-5 m. The side of the world, where it is planned to lay the terrace board, also affects the choice of step size. The instruction says that the greatest heating of the boards is usually observed from the southwest and south sides. Accordingly, in such places, it is desirable to perform seams with an interval of 2 m.

Ventilation

The coating must have good air circulation. To do this, only one rule should be observed: free niches in the space where the logs contact the base plates should remain unoccupied. This ensures unobstructed ventilation in the voids of the support system under the wooden flooring. But this only applies to cases with concrete slabs or other supports on which the logs are installed and the terrace board itself. Do-it-yourself laying on the ground also provides for the introduction of demarcating stone curbs into the design. Direct contact of the boardwalk and log with a lawn or ground is not allowed. For optimal circulation, in any case, it is necessary to provide open slots of 3 cm around the perimeter of the terrace.

End sealing

At the final stage of installation, the board-formed coating is given an integral decorative look. The surfaces of the profiles at the ends are closed by corners, as well as by F-shaped elements. For these purposes, special strips made of polymers can be used. For example, polypropylene or polyethylene may be the best solution for a terrace. The end corner of the KDP 3 x 3 x 0.5 cm is fixed with self-tapping screws having a semicircular head and a standard size of 0.4 x 3 cm.

The performance of these operations is important not only from the point of view of aesthetics, but also to increase the reliability of the coating - by means of high-quality sealing, the risk of cracks and other defects that a poorly laid terrace board sins can be eliminated. Do-it-yourself styling allows you to precisely approach the adjustment and correction of coating elements. However, it is desirable to perform these operations before sealing with end profiles and corners, otherwise the design will be unstable.

Also, do not forget about the conformity of the texture of the limiters and profiles used to the color of the flooring and wall. Often, such elements are sold unpainted, so you should prepare the paintwork composition with a suitable shade in advance.

Seamless styling technique

This method of installing the terrace can only be done if special material is used. This is a deck having a special profile for seamless joining. The main fasteners are also made using self-tapping screws. Installation is carried out either across the log or diagonally - in both cases, the reliability of the coating is quite high. In general, laying a seamless terrace board involves combining elements using the thorn groove method.

After fixing the first board, the next one is installed so that the profiles coincide. The seamless fastening system is more aesthetically pleasing and also does not need additional processing and protection. Depending on the characteristics of the decking, it is possible to form a coating with a durability of 20 years. The disadvantages of this installation include increased sealing, due to which ventilation suffers. But this problem is also solved by creating holes that are larger in diameter than the thickness of the screws. This, incidentally, is important to ensure the possibility of thermal expansion of the board.

Conclusion

Before those who decide to decorate the adjacent territory with an elegant and reliable terrace, there are many questions. This is the choice of material, and the definition of the laying pattern, as well as the search for a decorative solution. By and large, the answers to these questions will determine the quality characteristics of the terrace. The laying itself does not cause any particular difficulties, and if you follow the instructions for its execution, then in the future, the work done will not disappoint the home craftsman.