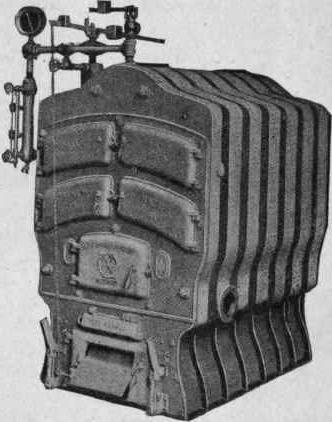

Solid fuel heating boilers are classified as equipment intended for use in non-gasified regions if there is no access to electric energy and liquid fuel. At the moment, about a fifth of the boiler equipment market is similar devices. Solid fuel heating boilers are used mainly by residents of the private sector, who prefer small-capacity equipment, about 30-100 kW.

Such equipment traditionally operates on wood chips,

coal, coke, pellets, firewood, peat briquettes. Solid fuel heating boilers of the pyrolysis type, in addition to the listed types of fuel, use gas emitted from it containing a large amount of CO, which, when passing through the nozzle, is mixed with air. As a result of this, an air-gas mixture forms, which comes into contact with the catalyst and ignites. The main advantage of such devices is the ability to control power in a wide range, a high level of efficiency, as well as almost complete combustion of fuel with the formation of a minimum amount of ash and soot.

The solid fuel

heating boiler , reviews of which can be easily found, working on wood, has a relatively low efficiency, at the level of 70-80%. For different types of fuel, the calorific value varies, for example, for firewood this indicator is less than for coal. This parameter is usually taken into account when designing the boiler: the furnace is smaller, the more calorific material is used in it. Such boilers do not support fully automatic operation; therefore, it is necessary to load fuel regularly. Coal is required to be loaded every 6-8 hours, and firewood - every 2-3 hours.

For solid fuels, the combustion process is difficult to regulate, so it is impossible to maintain any particular temperature regime in the room. Leading manufacturers are currently trying to get rid of this drawback, providing greater reliability, safety and efficiency. Modern wood-fired boilers have special burners that maximize the extraction of energy from fuel. Some boilers involve burning fuel by burning and burning. Such systems involve smoldering firewood in the lower part of the furnace, and the final burning of the resulting combustion products in an additional chamber. Due to this, wood fuel burns longer and more evenly. Modern solid fuel heating boilers provide maximum heat transfer to the coolant, and in combination with high-quality thermal insulation, this allows to achieve minimal heat loss.

Some models provide fuel to the boiler in automatic mode. These designs work by burning pellets - wood production wastes that are pressed into granules, the length of which is 5-70 mm and the diameter is 6-8 mm. Their production is carried out without the use of chemicals, which makes them environmentally friendly fuel. Such a solid fuel heating boiler, the price of which can be from 25,000 rubles or more, is much more efficient.