During technical progress, ventilation plays an important role, the design of which is carried out simultaneously with the preparation of the construction project of any building. We have long moved away from the construction of houses made of wood and natural building materials that normally let air through while maintaining heat. At the moment, they are widely used in plastic and polystyrene foam, which have poor breathability and emit harmful substances, such as formaldehydes. All these chemical building materials are used not only in industrial buildings, but also in the repair of residential premises. In order to save the situation at least a little, there was such a thing as “ventilation”. And this is not just a pipe that delivers fresh air. Therefore, the design of ventilation is a big science. A well-designed project makes it possible to breathe freely even near a hot machine in the factory.

Design Description

It is necessary to draw up a technical task. This is the initial document for the design of ventilation or other technical object. It indicates the necessary parameters of air in ventilated buildings, air exchange organization, types of coolants. During the preparation of such tasks, the following data is needed: the purpose of the building, the characteristics of building materials and coatings, doors, windows, sections of the premises and floor plans. The technological process and the operating mode are taken into account for industrial premises.

Ventilation calculation

First, the parameters of indoor and outdoor climates are calculated in accordance with regulatory acts (SNiP 23-01-99 “Construction Climatology” and SNiP 41-01-2003 “Heating, ventilation and air conditioning”).

Second, the necessary heat transfer is determined on the basis of regulations and the consumed air volumes per person per hour, taking into account heat influx.

Thirdly, when considering the features of the room, the types of necessary ventilation are determined: general or local, supply and exhaust or exhaust, natural, mechanical or mixed.

In conclusion, equipment is selected according to technical and economic criteria.

Ventilation design involves calculating the distribution of air in various ways: displacing or mixing, supplying and removing air from bottom to top, types of supply air jets, designing the number and types of air distributors.

Also, calculations of the air supply network are carried out: the sound pressure of the air during exit from the distributors, configuration, section of the air ducts, pressure loss in the network.

Then a graphic diagram is compiled, which displays a description of the adopted project of the ventilation system: plan, characteristics and location of technological units, a description of the materials and equipment used.

Types of ventilation

IN industrial building ventilation design different types of ventilation are included : simple systems for office premises, systems of medium and high complexity for large workshops in production.

Natural ventilation is an air exchange due to the difference in pressure, rarefaction of air and the use of wind power, without the use of special equipment and energy costs.

Forced - this is air exchange, which is carried out at the expense of technical devices: air conditioners, fans, etc.

Varieties of forced ventilation systems

By appointment, forced ventilation systems are divided into such types:

- Forced ventilation. It works by means of a fan, which supplies fresh air to the room, and due to the valve in the off state, air cannot move through the fan in either direction. Outflow occurs naturally, due to pressure through cracks in the windows and during door opening.

- Exhaust ventilation. It is produced with the help of a fan, which removes exhaust air from the room, while its inflow occurs due to leaks in the windows and when the doors are opened.

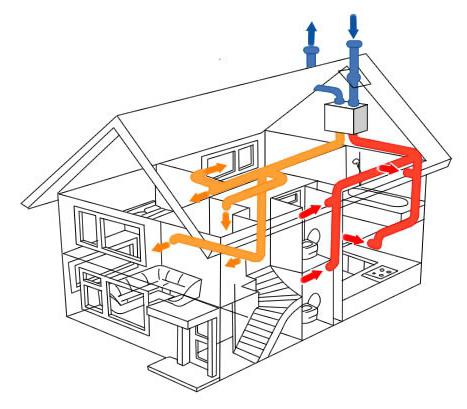

Design of supply and exhaust ventilation - This is a drawing that shows the movement of air in an exhaust system. In this case, the supply and exhaust of air occur simultaneously using special technological devices. This process is carried out by two types of air exchange. The first is a method of mixing air, when air is mixed from a clean room, and is discharged through exhaust valves. The second is the displacement method, when fresh air is supplied from below, and the exhaust is discharged from above in a natural direction.

More complex types of ventilation and their application

In addition to the natural and simplest forced species, there are also more complex ones. They are used when designing industrial ventilation. For example, in factories where a large amount of heat is produced during the production process, an “air shower” is used when a stream of chilled air is delivered at high speed precisely to the places of heat release. Another type of ventilation is an oasis. At the same time, cooled air is supplied to the enclosed area of the room and then distributed in the room. In production, where there is a lot of gas, dust, explosive substances, services involved in the design of industrial ventilation, oblige to use very complex types of ventilation, such as aspiration (this is a suction of polluted air). Exhaust systems used in production can be both general exchange (aspiration), and local (airborne suction, exhaust hoods). To comply with safety and environmental protection standards that are included in the design of ventilation of an industrial building, provide for the use of additional systems: air shields and curtains built into the ventilation system, anti-dust filters and those used from chemical impurities in the smoke.

Computerization of ventilation design

Ventilation design is a very complex and painstaking work. It requires great knowledge in this area. In order to facilitate the work of specialists, a program was created for the design of ventilation. And at the moment there are already a lot of such applications, both for large organizations and for not very experienced users. For example, Vent-Calkona operates on the basis of calculations based on Altshul formulas and allows for hydraulic calculation of the duct. There are plenty of similar programs on the information market, for example CADvent, AutoCAD, Ventmaster, etc., with which you can easily create projects in 3D, 2D graphics, drawings, and many other calculations.

Residential ventilation

The ventilation of a residential building with natural air exchange is designed according to generally accepted and prescribed in regulatory enactments standards. If you describe it in simple words, then everything looks as follows: through leaks in windows and through open doors or when ventilating through a window, clean air enters, and exhaust air is discharged through ventilation exhaust shafts. But due to the fact that now almost all houses have plastic windows, the natural flow is disrupted. We have to do the design of forced ventilation. One option is to install an infiltration supply valve, which is located on the wall or behind a heating radiator. In this case, fresh air will come already warmed up, which is very convenient in winter. Its removal in the house is also sometimes blocked by the fact that the ventilation bypass shaft is not located in every room, but mainly in the bathroom, toilet, kitchen and corridor. Therefore, for unobstructed air circulation in the apartment or in a private house, inlet doors are installed in the doors. If the natural ventilation of a residential building not doing well enough, a mechanical forced system is being installed. To do this, special fans are mounted in the bypass shaft. Such devices come in many forms. They are mounted on the wall at the entrance to the shaft or over the ceiling and mounted in the duct pipe. These fans are called hidden.

Standards for the design of ventilation systems

In any building, both in an industrial and in a private house, a ventilation system must be installed , but financial resources are not always enough to hire specialists for such an important and responsible work. Therefore, sometimes you have to calculate and install such structures yourself. In order for you not to make gross mistakes in the calculation, we give an example of how the calculation and design of ventilation in a private house is done. All systems differ from each other in performance, therefore, according to accepted standards, it should have the following indications:

- for residential premises - 3 m³ per hour per 1 m²;

- for sanitary facilities - 50 m³ per hour per 1 m²;

- for separate bathrooms - 25 m³ per hour per 1 m²;

- for living rooms there must be an influx of air.

Types of ducts and ventilation installation

During the installation of ventilation , air ducts, fasteners, filters and fittings are used. The main instruction is the design of ventilation and installation. Everything is produced according to this project, where a specific type of duct is indicated. Rigid structures are rectangular and round. Round air ducts have the smallest air resistance, rectangular air ducts have a slightly higher resistance, and flexible and semi-flexible air ducts have the largest resistance due to the fact that they are corrugated. Therefore, the main highway passes according to the data provided, which are included in the design of ventilation, and installation performed using rigid structures, while flexible ones are used as connectors. All air ducts must be insulated with mineral wool to prevent condensation.