The need for prefabricated and reliable buildings for agricultural needs, warehouses, workshops and industrial premises has led to the creation of a structure - a metal hangar, the price of which can be equal to 20,000 rubles. The popularity of such buildings is constantly growing, today you can see them as private garages, sports facilities, office buildings and refrigeration complexes.

There are companies on the market that specialize in the manufacture of such hangars. However, under certain conditions, you can create similar designs yourself, for this you only need to be able to use the tool and correctly create the project.

Design

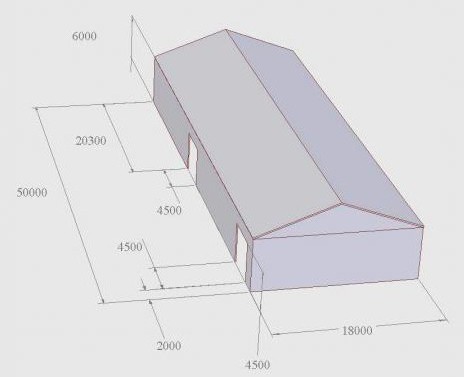

Metal hangar should be designed in the first stage. Without this, it will not be possible to erect a structure, buy materials and obtain the necessary permits. In the project you will be able to display the calculations of the loads on the structure, which is important for metal prefabricated buildings. If we consider the most common types of hangars, it can be noted that polygonal and arched are the most complex.

A metal hangar, the price of which, perhaps, will allow you to make a choice in the direction of a particular model, requires the presence of design skills and experience. But tent and direct-wall hangars with gable roof structures will be easier to build, however, it is advisable to have some experience in the design. Development and creation of the project are carried out according to a specific algorithm. At the first stage, it is necessary to design the foundation, then - the frame, load-bearing and wall structures, as well as the roofing system. It is important to design engineering systems, such as:

- ventilation

- electrical wiring;

- water supply;

- sewer.

Light metal hangars can be installed on monolithic, tape and column-tape bases. Depending on the planned loads and sizes, the material for the frame should be selected , it can be a channel, a pipe with a square profile, an I-beam or a sigma-shaped profile. The connection of all elements must be carried out using high-quality bolts and connecting fittings.

A bit about the cost

It is also worth remembering that a certain amount will have to be spent on a metal hangar. For example, for a one-story, but low warm hangar, the price will be lower compared to a structure that has the same height, but two floors and rooms inside.

The distance between the supporting columns and the arches of the frame should be approximately 3 m, while the length of the hangar should be a multiple of this step.

Hangar Construction: Foundation

Before you create a metal hangar, you must build a foundation. The land for construction is leveled, and then you can begin construction. The base can be tape, pile or monolithic-plate. The construction process of the foundation will be considered on the example of a slab foundation, since it is considered the most time-consuming to create. Projects of metal hangars provide for the mention of the construction area, taking into account which it is necessary to level the territory, in the corners and under the supporting columns, make 20-cm holes where the piles will be installed. After a layer of sand is poured inside, and then a reinforcing frame for each support. The length should be chosen so that about 50 cm are visible above the surface of the rods. The frame is poured with concrete, and then left to solidify.

When a metal hangar is being built, the next step is to create a formwork around the perimeter. Its height will be equivalent to the thickness of the plate. After the soil is removed, the fertile layer is removed and covered with a 15 cm layer of sand. It is tamped, a layer of rubble is laid on top. The layers are compared and compacted, and the latter is formed from gravel. The thickness of the layers should be approximately 5 cm below ground level.

Now you can create a reinforcing frame by area, there is no particular difficulty in this, the main thing is to lay pieces of stone or brick under the frame so that the rods are at some distance from the top layer. Excess pieces of reinforcement from the frame are cut off so that they do not stick out from the foundation, after which concrete is poured, and the base is left to gain strength for a month.

Assembly and installation of the frame

If you decide to build a metal hangar, then the next step will be to create a frame. It is necessary to begin work with the installation and fixation of the support heels. They should be placed around the perimeter, the distance between them should be equal to the step between the frames of the frame. On the concrete surface, points are marked for the holes where the anchors will be installed, they must be drilled. After completion, the heels are placed in places and fixed to the concrete base with bolts.

The next step will be the assembly and installation of columns. The simplest option for their installation involves connecting two channels between themselves. A part of the supporting heel is clamped inside. In order to simplify the assembly and lifting of the column, its parts are connected to the ground and fixed to the heels with one bolt. At the same stage, a connecting curtain rod is installed, and then firmly fixed. The column rises vertically and secures, and on the ground a farm is assembled from floor beams. You can’t do without a crane that will lift the elements up. They need to be fixed to the supporting columns.

Methodology

When prefabricated hangars line up , an I-beam may be present in the structure. In this case, the support heel is welded to its base, vertical installation and fastening are carried out using a crane. The frame can be assembled on a flat surface, while it will consist of a truss and two columns. With the help of a crane, it will be necessary to lift and put this part in place. As soon as all frames of the frame are lifted and installed, additional rigidity can be achieved using vertical ties, horizontal runs.

Frame cladding

Prefabricated hangars must have a casing, which is installed in one of the existing methods. The simplest option is cold cladding using corrugated sheets. Each subsequent sheet should be stacked from bottom to top with a slight overlap on the previous one. Sheets are strengthened with metal screws. The construction of metal hangars is carried out by the same methodology in the roof area, where the sheets are installed taking into account the formation of the ridge tide.

Conclusion

The construction of metal hangars is carried out according to other technologies, which include the installation of sheathing material in a warm manner. In this case, sandwich panels are used. This technique is as simple and preferable as possible, as it allows you to form a structure in the shortest possible time.