In working with various electronic or radio components, both specialists and amateurs use a special mixture - solder flux. Its composition can be very different. Soldering flux today as a product is presented in a wide range: in the form of powder, paste or liquid. The composition of the substance can be organic and inorganic. The LTI-120 flux is very popular among consumers.

What is a substance?

During soldering during heating, parts are able to oxidize. As a result of the formation of an oxide film on their surfaces, such parts are poorly wetted by solder. In order to dissolve this film and promote soldering, special substances are used, which are called solder fluxes.

Gumboil LTI-120 is a dark colored liquid. For transportation and storage of this substance special bottles, cans or bottles are provided. LTI-120 belongs to the corrosive, low-temperature, activated flux groups. Sometimes colloidal formations may be present in small amounts in the composition.

Who is the manufacturer?

This flux is supplied to the market from various manufacturing companies. But the substance is always marked the same: LTI-120. It was developed by employees of the Leningrad Technological Institute.

Destination

LTI-120 is used in the following cases:

- When you need to remove the oxide film from the surface of the workpiece.

- When it is required to prevent oxidation of metal or solder during operation.

- If necessary, reduce the surface tension in the molten solder.

Key Specifications

- LTI-120 has a temperature range of 160-350 degrees.

- The highest activity of a substance is observed at temperatures from 250 to 300 degrees.

- The substance does not dissolve in water, as a result of which it is not washed off from surfaces. Since this flux is considered neutral, there is no need to remove its residues after work. If desired, this can only be done with acetone or alcohol. According to reviews of some masters, vodka can also be used for this purpose.

- Flux interacts well with both soft tin-lead and silver solders.

- When working with this soldering flux, it is not necessary to ventilate the room.

What materials can interact with?

LTI-120 is recommended for soldering parts, the manufacture of which uses the following materials:

- stainless steel;

- zinc;

- nichrome;

- lead;

- cadmium;

- palladium;

- copper, as well as its alloys.

Often, this flux is also used for soldering silver products.

Composition

LTI-120 consists of the following chemical elements:

- Pine rosin brand "A" (25%).

- Triethalomine (2%).

- Diethylamine hydrochloride (3 to 5%).

- Ethyl alcohol (90-95%).

The composition of LTI-120 is simple. In the absence of this solder flux on the counter, it can be done independently. This is often practiced by many masters, making flux from the appropriate components.

How does the tool work?

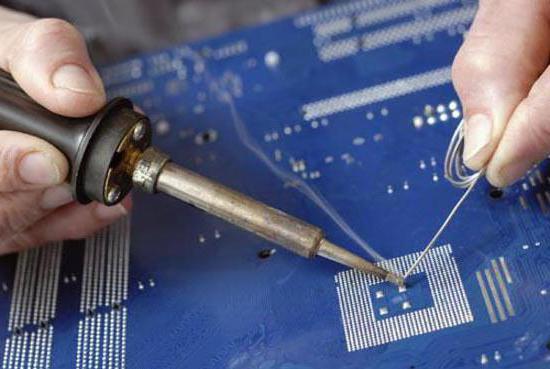

Using this substance, you can both solder wires and work with boards. Due to its liquid consistency, flux is not very convenient to use at the beginning of soldering, as it is spread with a thin layer and dries very quickly. To fix this, before soldering the wires or boards, it is necessary to allow the flux to stand a little. To do this, pour a small dose of the substance for a while in a separate container (this could be a bottle cap). This procedure is recommended to be performed several days before soldering work. During this time, the flux should slightly dry and thicken. Before soldering circuit boards or other electrical and radio components, check the condition of the substance. It should resemble liquid honey. In such a consistency, LTI-120 is conveniently applied with sharp toothpicks to the desired surface. If the solder flux turned out to be very thickened, it can be diluted a little with a small amount of alcohol or a new portion of the same LTI-120. When working with printed circuit boards, it is important to ensure that when tinning their tracks there is no overheating. Otherwise, these tracks may fall off. It is easy enough to smear them with LTI-120, and then draw a soldering iron with a small amount of solder over each of them. This will ensure high-quality tinning of the tracks and give an almost mirror-like surface.

When soldering wires, tinning, according to experts, is best done separately for each wire. If the wire is soldered to the printed circuit board, it is recommended to make a small hole in it. Only after that, a tinned wire can be inserted into it from the back of the printed circuit board and soldering started. This method will provide reliable fastening: with a strong jerk, the track will not come off.

As many manufacturers claim, these solder fluxes are inactive and do not need to be washed off. But judging by the numerous reviews, some masters and radio enthusiasts are still confused by the presence of additives, and after finishing work, they prefer to wash off the remains of fluxes. This is done using wide brushes that are pre-wetted with alcohol. Some use regular brushes and plenty of tap water. According to the assurances of such masters, there is nothing wrong with the fact that a ready-made board is wetted with water. The main thing is then to dry it thoroughly.

Using this solder flux, one should not forget that this is a chemical and working with it requires compliance with safety rules. During tinning, the mucous membranes of the stomach and eyes should be protected. Work is carried out using a brush, which is attached to the set of LTI-120. If soldering flux gets on the skin, the affected areas should be washed with plenty of water using soap.

Cost

One of the advantages of this solder flux is its low price. Mostly, these liquids are sold in special bottles designed for 30 ml, or small bottles of 20 ml.

Each of them is completed with one brush. In such containers, flux LTI-120 costs up to 50 rubles. For industrial enterprises, larger containers are provided - half-liter bottles are used. Depending on the manufacturer, the cost of such a capacity ranges from 300 to 500 rubles.

Storage Features

Soldering LTI-120 refers to fire and explosive substances. In this regard, it is recommended to store it especially carefully. It is desirable that such a place was hermetically sealed dishes. The container with this substance must not be placed in direct sunlight or near open sources of fire. Despite the fact that the soldering flux is considered neutral, some owners still recommend that the room in which the soldering was carried out be ventilated after completion of work.

Consumer opinions on LTI-120

Reviews about the flux of this brand are mostly positive. The substance has the following advantages:

- The presence of a special small brush in the kit for LTI-120. According to numerous consumer reviews, working with such a brush is very convenient.

- The flux is not electrically conductive.

- LTI-120 is ideal for tinning wires, printed circuit boards and other electronic components.

- The substance does not require mandatory disposal after work.

- Sold in small 20 ml vials. This, according to the masters, is very convenient, since such a capacity does not take up much space in the tool box, and a small amount of liquid is enough for a long time.

- Low price.

Flux Lux

The LTI-120 modification: Lux flux is very popular among professionals and lovers of radio electronics. This substance also has a very high performance. The only thing that distinguishes the new flux from the base LTI-120 is that it does not dry out so quickly. This is due to the presence of water in its base base. The LTI-120 Lux contains no volatile solvents or ethyl alcohol. The rest of the modified solder flux consists of the same components as the basic version. LTI-120 Lux is used not only for soldering work. It is highly appreciated by consumers as an effective tool for cleaning the surfaces of parts from pollution. Compared with LTI-120, the new version of the flux is not so dangerous. Some consumers even wash their hands. A distinctive feature when using Lux is hissing and the formation of steam after application to the surface of the part.

Conclusion

Soldering flux LTI-120 and its modification are produced by various manufacturers. Today on the market there are many fakes of this substance. To get real and high-quality products, just smell such a flux. Forgery is characterized by a sharp and very strong smell, reminiscent of ammonia. This LTI-120, according to experts, has a pleasant smell.