Panels made of honeycomb or monolithic polycarbonate due to their practicality have found application in many fields of construction and industry. In particular, plastic sheets are widely used in arranging various designs and structures, forming a reliable roofing. If a suitable polycarbonate fastener is selected, the material will provide optimum strength and mechanical protection characteristics. Fixing can be carried out to any materials, however, metal frames and surfaces imply the greatest responsibility in choosing the method of fastening.

Polycarbonate Installation Procedure

The work consists of several stages. First of all, measurements are made of polycarbonate required for laying on a specific surface or frame. Next, you need to prepare sheets of the given parameters. One of the main advantages of polycarbonate is its ease of processing. You can cut it with an ordinary hacksaw and scissors. Then, the polycarbonate is directly attached to the frame using the fixing elements. At the final stage, an analysis of the quality of the work done is carried out: the joints of the plastic sheets, the reliability of the fasteners and the condition of the honeycombs (ribbed polycarbonate cells) are checked, which should be clean.

How to fix monolithic polycarbonate?

For the installation of sheet (monolithic) polycarbonate, special hardware, profiles and galvanized tape are used. This variety differs from honeycomb plastic in high density and rigidity. In terms of the use of fasteners, these qualities are a plus, although technically they make the process of drilling and introducing elements a bit more difficult. The most common fastening of polycarbonate with self-tapping screws, but to obtain a stable and durable design, it is also recommended to use profiles and a special tape. If there are no special requirements for the construction, then it is possible to limit ourselves to ordinary hardware, but provided that the installation is accompanied by the use of thermal washers.

Features of fastening cellular polycarbonate

Panels of this type are fixed with the same elements as monolithic analogues. But cellular polycarbonate has its own design features, which are important to consider when installing the material. Open cells can become clogged with dirt, water and insects, which affects the technical and aesthetic qualities of the coating. To prevent clogging allow special tapes that are glued to cellular polycarbonate. The fastening of the protective strip allows insulating the internal space of the material. There are steam transmission and sealing tapes. It is preferable to opt for the first option, since it minimizes the possibility of clogging of the cells, but does not create a barrier to the removal of condensate and ventilation. Sealing tapes, in turn, provide the maximum obstacle to any contact of the honeycomb with the external environment - including not allowing air and moisture to penetrate.

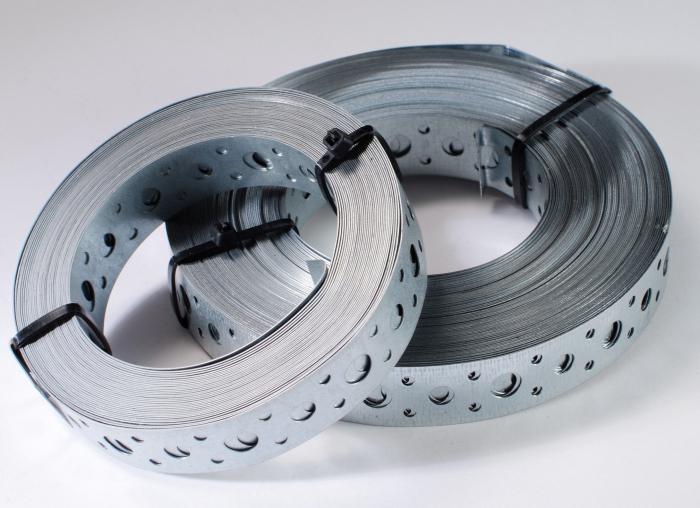

Galvanized tape

This is a new way of fixing polycarbonate sheets, which use metal tapes that have undergone anti-corrosion treatment. The fastener elements are coupling clamps with a standard width of 20 mm and a thickness of approximately 0.7 mm. Thanks to galvanization, this material is not subject to chemical destruction under the influence of rust, and also provides structural strength. If polycarbonate is attached to metal in a greenhouse, it is recommended to provide for the possibility of complex fixation of tapes, which will ensure the screed of several sheets of material at once.

Galvanized tape fastening technology

The main advantage in installing such tapes is the absence of the need to intrude into the structure of polycarbonate itself. That is, it does not need to be drilled or to make special perforations for specific fasteners. Tapes provide a fairly tight fit of the material to the elements of the frame. It is desirable to use such a method on arc and arched structures. At the same time, in the supporting arches of the same greenhouses, you will not have to create holes for hardware, since the galvanized tape for attaching polycarbonate acts on the principle of tensile force.

The installation process begins with fixing the position of the plastic sheets. Laying of several elements is carried out with an overlap. Next, you need to divide the tape into two parts - each of them is initially attached at the base of the structure. The segments are superimposed exactly along the line of convergence of the panels and are fixed with each other by nuts. Thus, the polycarbonate fastening tape provides a tight connection of sheets, which does not imply damage to the material and creates a rather attractive appearance of the entire structure.

The nuances of the operation of galvanized tapes

Although this method of attachment is the most technological and has many advantages, there are certain disadvantages in it that should be taken into account. They are mainly due to the fact that the fixation is realized in the open. Accordingly, if a greenhouse with polycarbonate is unattended for a long time, there is a risk of its quick and inconspicuous dismantling - unscrewing a few screws will not be difficult for an attacker armed with pliers. In addition, the fastening of polycarbonate with a metal tape 2-3 cm protrudes outward, which often causes inconvenience when in close contact with the surfaces of the greenhouse.

Thermal washer

Before the appearance of the thermal washer and galvanized tape, polycarbonate was fixed with ordinary screws. This is a simple and cheap method in which the relative reliability of the structure is ensured. The disadvantages of using such hardware are due to the physical and operational properties of polycarbonate, which make its structure changeable at temperature extremes. Using a thermal washer eliminates negative factors - the element naturally adapts to external conditions, evenly distributing the clamping force. The combined fastening of polycarbonate to metal is also practiced, in which the screws together with the thermal washer are twisted through a galvanized tape. Thus, the maximum reliability of the sheathing of the metal frame is achieved and the disadvantages inherent in the single use of tape clamps are eliminated. On the other hand, this is the most costly and time-consuming polycarbonate installation technology, which in some cases does not justify itself.

Profile mount

These are special devices designed to fasten or join polycarbonate sheets. The design of such profiles contains two elements - the base and the cover. With their help, a double-sided clamping of the edges of the material is provided, which does not require drilling and direct twisting of the sheets. Only the base is fixed in the appropriate places where the installation is planned. Such polycarbonate fastening is advantageous, first of all, by reliability and tightness, but besides this, the owner also gets an impeccable appearance of the coating. Since profiles are usually made of the same polycarbonate, they are visually merged with the main sheets. It is enough to choose the elements that are suitable in color.

There are aluminum profiles with a similar design. They provide the same quality of connection as the galvanized tape for attaching polycarbonate, but at the same time eliminate flaws in the clamping installation method. That is, to spin this system is not so simple - the presence of self-tapping screws and a strong clamp of profiles complicate this task for an attacker.

Double and side mount

The choice of installation method of polycarbonate is also affected by the location of the attachment points. There are two approaches to installation - run and double-sided. The first option is used if a large area is covered with polycarbonate. To exclude possible deflections of the sheets, several fastening runs should be made across the location of the ribs of the material. Depending on which polycarbonate fastener is used, the pitch can be 40-50 cm. The use of a double-sided installation is advisable if a small area is sheathed - in this case, the fastening lines are made along the longitudinal sides of the polycarbonate sheets.

The run-through mounting method focuses on the number of fixation points, so it makes no sense to use expensive installation tools. And vice versa, the two-sided version involves only two installation lines, so for the implementation of such fasteners it is worth using combined or profile installation methods.