Today, electricity surrounds people everywhere. To ensure operability, you often have to connect the wires to each other. At this moment, the main question arises, which is better - twisting or terminal block? There is no single answer to this day.

General information on connection methods

Here it is worth starting with the fact that the twisting of wires is a connection method that appeared at about the same time as the electrification itself appeared. However, a huge amount of time has passed since then. The development of technology has led to the emergence of a newer method - terminal blocks Wago. On the one hand, after such explanations, it becomes very simple to answer the question of which is better - a twist or terminal block. Newer technologies are always ahead of the old ones, it is more convenient and practical, as well as more aesthetically pleasing. But in this case, “Vago” has certain disadvantages.

Today we can say that both methods have the right to exist and exploit. However, for example, according to the PUE it is impossible to carry out normal twisting, it is necessary to carry out either soldering or welding.

When answering the question of which is better - a twist or terminal block, it is necessary to take into account an important fact - exactly where the wires are operated. Suppose a fire inspectorate at all objects to be inspected will quickly suppress normal twisting. This is due to the fact that very often a poor-quality connection becomes the cause of the fire. Copper and aluminum wires are twisted together, hard and soft, etc. All this ultimately may well cause a fire.

Terminal application

So which is better - twist or terminal block? It is important to understand that Vago devices are not a panacea for protection and reliability, they can also fail. Such equipment is usually designed for a load of 3.5 to 5 kW. In the case of terminal melting, you need to understand that a voltage of higher power flows than is necessary in the network. Usually this is a problem with the absence or poor-quality operation of the circuit breaker, which should monitor this. Most often, such a problem arises in old houses where there is simply no such equipment.

You can take as an example the excellent performance of the terminals in new buildings. At such facilities, Wago appliances are commonly installed. Residents of such houses almost never complain about a problem with the wiring. At the same time, it must be understood that for such consumers of electric energy as boilers, washing machines, dishwashers and other equipment, separate power lines are laid. Their main difference from ordinary ones is the absence of compounds; they are always integral. Terminals are used only for laying outlet groups, for lighting, etc. That is, for those consumers who initially work with low voltage power.

It turns out, if you choose between twisting or terminal block, the second will always win? This is not entirely true. In new buildings, twisting without welding and soldering is also used, but with one condition. For it, special PPE terminals are used. They managed to establish themselves as high-quality devices for connecting wires. But they have a certain disadvantage. Arranging wiring with PPE terminals is a time consuming task. And on large construction sites, it is precisely the factors of time and speed that often play a decisive role.

Cable Connection Methods

When wondering what is better - twisting or terminal block, you need to understand where such connection methods can be applied at all. One common connection method is to use self-clamping terminal blocks. Very often when working with electrical wiring, you have to connect aluminum and copper wires to each other. In such cases, the twist option disappears immediately, since the cables differ in material. Before the widespread distribution of Vago products, it was believed that a bolted connection was best. At present, two types of Wago devices are used.

The first type of spring connection is universal terminals with a tension spring. The second type is flat spring specialized terminals. The first option is used if it is necessary to connect stranded, that is, soft wires. The second option is operated in places of switching single-core (solid) wires.

The process of connecting via terminals is quite simple. Insert the cable into the spring-loaded clamp until it stops. In this case, optimal pressure will be created on the contact, regardless of its cross section. This type of clamp does an excellent job of crushing the wires of the wire to the busbar, eliminating the possibility of such a problem as spontaneous disconnection. To ensure the convenience of measurement or inspection, the clamp has a special hole that allows you to get to the busbar. In the case of a correct connection, the possibility of short circuiting and touching other live components will also be completely excluded.

Benefits of Wago Products

Which is better - a twist or terminal block Wago? To more fully answer this question, you can consider the advantage of the terminals.

- One of the most important advantages is that the quality of switching with the Vago spring terminal will be at a high level, regardless of how qualified the master performed it.

- Such equipment boasts a high connection speed and the absence of the need for specialized tools.

- High protection against accidental contact with any current-carrying parts of the device is provided.

- Reliability of contacts is at a very high level.

- The terminals will allow you to make the necessary changes to the wiring, without violating the quality of the connection.

- Each wire has its own separate socket.

- The clamps have good impact resistance and vibration resistance.

- In automatic mode, it is possible to control the clamping force on the wire.

- There is no need to carry out special work in the service sector.

- The electrical conductors themselves in such devices are characterized by good resistance to damage.

- Last but not least, the advantage is a good value for money.

Wago 222 Series Products

This company produces many varieties of its products. One of the fairly popular series is the Wago 222 terminal block.

This product is intended for connection or branching of both multicore and single-core wires. They are allowed to be used in circuits of only alternating electric current with a maximum voltage of 380 V and a frequency of 50 Hz. Initially, the Wago 222 terminal block was intended for switching copper conductors. However, it is allowed to connect aluminum cables if the device is filled with conductive paste. In addition, the equipment is universal, which allows it to be used both for lighting devices and in switchboards.

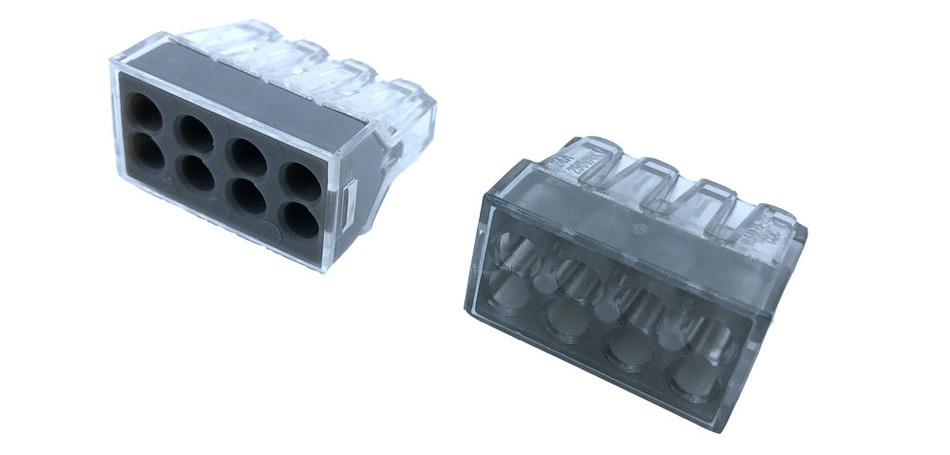

As for the external data of the Wago 413 terminal block (full name of the series 222-413), it is very similar to such other well-known series as 273 and 773. It is quite small in size and has good protection of live parts. A small feature of the device is the presence of a test hole. This development is one of the last, and now it has become very popular in the energy sector. Wago 2, 3-wire and 5-wire terminal blocks are available. In other words, it is possible to simultaneously connect two, three or five conductors. Allowed switching cables with a diameter of 0.08 to 4 mm 2 .

The main characteristics of the device are as follows:

- rated operating voltage of 400 V or 4 kV;

- rated operational current value for a cable with a diameter of 4 mm 2 - 32 A, for a cable of 2.5 mm 2 - 24 A;

- the cross-section of single-core or multi-core conductors should be in the range of 0.08-2.5 mm 2 ;

- connection of thin-wired cables is allowed with a cross section of 0.08-4 mm 2 .

Wago 221 Series

The Wago 221 terminal block is a versatile lever-type compact connecting device. With its help, conductors made of copper materials with a diameter of 0.2 to 4 mm 2 can be reliably switched. It is allowed to connect both single-core and multi-core cables. A feature of the 221 series is that it is great for creating a temporary connection, as well as a permanent one. In electrical engineering, such devices are usually used to connect wires in switchboards, junction or junction boxes.

Another feature of such switching devices is that they are perfectly suitable for use in a conventional network of houses with 220 V or 380 V, and for connecting various components of low-voltage equipment. In addition, there are a number of specific advantages to this series.

- High installation speed, which is accompanied by a minimum risk of error. Even when assembled by an inexperienced specialist, poor connection is virtually eliminated due to the transparent case and ease of assembly.

- High reliability of the connection is accompanied by a low cost of equipment.

- This series of terminals is conveniently used in confined spaces where access to wires is difficult for any reason.

- To arrange the connection, you need only a minimal set for stripping the cable insulation. There is no need for specialized installation equipment.

- As for the rated operating current, for example, it is 32 A. It is also important to note here that if all the connection rules are followed, the terminal will not overheat when the current rises above the rated limit.

Other Wago products

The Wago 4 terminal block , for example, designed to connect four wires, has these parameters. Firstly, it is designed to connect only single-core wires. Secondly, a spring-loaded version is used as a connection clamp. Thirdly, the cross section of the connected conductors can be from 0.5 to 2.5 mm 2 .

As for the nominal parameters, for voltage it is an indicator of 450 V, and for current - 24 A.

Today there is a special development - the 773 series. It was specially released for operation in switchboards. It can be Wago 5 773 series terminal blocks or others. In this case, the number 5 will indicate the number of possible connected wires. In general, depending on the needs and model, from 2 to 8 cables can be connected. As for the clamp model, it is flat spring. It is allowed to connect single-core electric cables with a cross section from 0.75 to 2.5 square millimeters to such a terminal block. Most often, 1.5 and 2.5 mm 2 conductors are used. Rated operational voltage - 400 V.

Another 273 series is also used in switchboards. However, here the cross section has a broader range - from 1.5 to 4 mm 2 . The rated operating voltage is the same as the 773 series, and this is no accident. Most often, 273 terminals are used as a complement to the previous ones. That is, the 273 series may be 3x. Wago terminal blocks in this category, i.e. 273, are usually used in cases where it is necessary to connect conductors with a cross section of more than 2.5 mm 2 .

There are separate switching devices of the 224 series, which are intended for use only with lighting devices, for example. These Wago 3-224 terminal blocks, that is, can be used for switching three wires. There is an assembly in which there are only two cable slots. The operating voltage of the device is 400 V, and the cable cross-section can be 0.5-2.5 mm 2 . The peculiarity of this equipment is that on the lamp side, the clamps are designed for multicore and thin-core cables. On the network side there is a flat spring clip, which is designed to connect a solid wire.

PPE type clamps

So, which is more reliable - twisting or terminal block? As noted earlier, for twisting, you can use a special device - a connecting insulating clamp or PPE. It can be used only for single-core cables, whose total cross-sectional value will not exceed 20 mm 2 , and the minimum will be 2.5 mm 2 . The housing of such devices is usually made of insulating material. It can be polyamide, nylon, refractory PVC. Due to this, there is no need for additional subsequent isolation.

The connection takes place according to the following principle: insulation is removed from the end of the wire by about 10-15 mm. Cables are assembled in one bundle, and PPE is wound on top of them. It is necessary to wind up clockwise and to the stop. Caps of this type are very easy to install and quite convenient. But they have a significant drawback - they are much inferior to the terminal blocks as a twist, so they are used much less often.

Why not twist?

Here it’s worth immediately starting with the fact that, according to the rules of electrical installations (PUE), twisting is completely prohibited, although most connections begin with it. In order for the forbidden twist to become a number of permitted connections, it must be additionally equipped with a special device. In this case, PPE became such a device. Plastic caps with a metal spring inside should firmly hold the wires. However, their small size led to the fact that it was necessary to reduce the length of the twist to 10-15 mm, and this, of course, negatively affects the quality and reliability of the connection.

Separately, it is worth noting that there is the possibility of soldering or welding twisting, as an additional way to increase the reliability of switching. However, this method is much more time-consuming than using a conventional terminal block. But, on the other hand, if you compare only the reliability of the connection, then welding or soldering will no doubt be the best choice.

Materials for terminal blocks "Vago"

In the manufacture of its products, this company uses polyamide as the main material for insulation of live parts of the equipment. This choice is due to the fact that polyamide is very poorly flammable, has good resistance to corrosion, as well as the possibility of self-extinguishing.

As for the temperature conditions, the polyamide is able to withstand the load for a short time of 170 degrees Celsius, or -35 degrees.

The current-carrying elements themselves are made of special electrolyte copper. In addition, they have a coating of tin and lead. All this provides reliable protection against corrosion. Since most of the terminal blocks have a spring-type clamp, it was necessary to make a spring of high-quality steel. Chrome-nickel steel, which is characterized by a high tensile strength coefficient, was excellent for these purposes.

A significant plus in the design is that after connecting single-core and multicore wires it is possible to change the initial configuration. There is no need to use a special tool.

As for reviews of these compounds, they are as follows.

Twisting is still used, but usually in private homes for arranging a network where there is no connection of energy-intensive consumers. However, more and more people are responding positively to the use of Wago terminals. They provide much greater reliability, and hence safety against fire due to poor contact. The advantage of twisting in the opinion of home masters was that they did not have to spend financial resources on additional equipment. However, today these devices are so small that neglecting the increased security from their purchase, it becomes impractical.