It is difficult to overestimate the significance of measurements in the life of a modern person. With the development of technologies, the question of the need for them is not at all worthwhile, but principles and methods that make it possible to increase the accuracy of measurements come to the fore. The spectrum of areas in which systems and measurement methods are involved is expanding. At the same time, not only technical and technological approaches to the implementation of these operations are developed, but also the concept of their application. Today, the measurement method is a set of techniques or techniques that allow you to implement one or another principle of determining the desired value.

Principles of Measurement Methods

The basis of any measurement method is a certain physical law, which, in turn, is based on a particular natural phenomenon. In metrology, physical phenomena are often defined as effects that determine the pattern. Specific laws apply to measure different quantities. For example, current measurement is based on the Josephson effect. This phenomenon, in accordance with which a superconducting current passes through a layer of dielectrics separating superconductors. To determine the characteristics of the absorbed energy, another Peltier effect is already used, and to calculate the speed, the law of change of the radiation frequency, discovered by Doppler, is used. In a simpler example of determining the mass of an object, gravity is used, which manifests itself in the weighing process.

Classification of measurement methods

Usually, two signs of separation of measurement methods are used - by the nature of the change in values depending on time and by the method of obtaining data. In the first case, statistical and dynamic techniques are distinguished. Statistical methods of measurement are characterized in that the result obtained does not change depending on at what point they are applied. These can be, for example, the basic methods of measuring the mass and size of an object. Dynamic techniques, in contrast, initially allow for fluctuations in performance. These methods include those methods that allow you to track the characteristics of pressure, gas or temperature. Changes usually occur under the influence of environments. There are other classifications of methods, due to the difference in the accuracy of measurements and the conditions of the operation. But they are usually of a secondary nature. Now it’s worth considering the most popular measurement techniques.

Comparison Method with Measure

In this case, the measurement occurs by comparing the desired value with the values reproduced by the measure. An example of this method is the calculation of mass using a lever- type balance . The user initially works with a tool in which certain quantities with measures are embedded. In particular, using the system of balancing with weights, he can fix the weight of the object with a certain degree of accuracy. The classic pressure measuring device also in some modifications involves determining the value by comparing it with indications in an environment in which the initially known values are already operating. Another example concerns voltage measurement. In this case, for example, the operation characteristics of the compensator will be compared with the known electromotive force of a normal element.

Addition measurement method

Also a fairly common technique, which finds application in various fields. The method of measuring the value of the addition also provides for the presence of the desired value and a certain measure, which is known in advance. Only, unlike the previous method, the measurement itself is carried out when comparing not with the calculated value, but under the conditions of its addition with a similar value. As a rule, methods and means of measurement on this principle are more often used in working with physical indicators of the characteristics of an object. In a sense, the technique of determining quantities through substitution is similar to this technique. Only in this case, the correction factor is provided not by a value that is similar to the desired value, but by the readings of the reference object.

Organoleptic method of measurement

This is a rather unusual direction of metrology, which is based on the use of human sense organs. There are two categories of organoleptic measurements. For example, the element-wise method allows evaluating a specific parameter of an object without giving a complete picture of its characteristics and possible operational qualities. The second category represents a comprehensive approach in which the method of measurement using the senses gives a more complete picture of the various parameters of the object. It is important to understand that a comprehensive analysis is often useful not so much as a way of taking into account a whole group of characteristics, but as a tool for assessing the overall suitability of an object in terms of its possible use for a specific purpose. As for the practical application of organoleptic methods, they can be used to evaluate, for example, ovality or the quality of the cut of cylindrical parts. In a complex measurement by this method, one can get an idea of the radial runout of the shaft, which is just discovered after analysis of the same ovality and characteristics of the outer surface of the element.

Contact and non-contact measurement methods

The principles of contact and non-contact measurement have a significant difference. In the case of contact devices, the value is fixed in close proximity to the object. But, since this is not always possible due to the presence of aggressive media and difficult access to the measurement site, the non-contact principle of calculating values has also become widespread. The contact method of measurement is used in determining such quantities as mass, current, overall parameters, etc. However, when measuring extremely high temperature it is not always possible.

Non-contact measurement can be performed with special models of pyrometers and thermal imagers. In the process, they are not located directly in the target measurement medium, but interact with its radiation. For a number of reasons, methods for measuring temperature by the non-contact principle are not very accurate. Therefore, they are involved only where you need to have an idea of the characteristics of certain zones or areas.

Measuring instruments

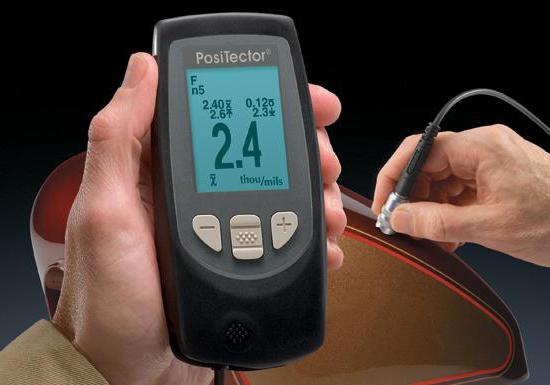

The range of measuring instruments is very extensive, even if we talk about a specific area separately. For example, thermometers, pyrometers, the same thermal imagers and multifunctional stations with the functions of a hygrometer and a barometer are used to measure temperature alone. Recently, loggers equipped with sensitive probes have been used to take into account humidity and temperature readings in the complex. When assessing atmospheric conditions, a manometer is often used as well - this is a pressure measuring device, which can be supplemented with sensors for monitoring gas environments. A wide group of devices is also presented in the segment of means for measuring the characteristics of electrical circuits. Here you can highlight such devices as a voltmeter and ammeter. Again, as in the case of weather stations, the means for taking into account the parameters of the electric field can be universal - that is, taking into account several parameters at the same time.

Instrumentation and automation

In the traditional sense, a measuring device is a tool that provides information about a particular quantity that is characteristic of a particular object at a given moment. During the operation, the user registers the readings and subsequently makes decisions based on them. But increasingly, these same devices are being integrated into a set of equipment with automation, which, on the basis of the same recorded readings, independently makes decisions, for example, on the correction of operating parameters. In particular, instrumentation and automation equipment are successfully combined in gas pipeline complexes, in heating and ventilation systems, etc. For example, taking into account the pressure in the pipeline will signal the automatic system to increase or increase the flow rate of the working medium - water or the same gas.

Measurements and Errors

Almost any measurement process to some extent involves the assumption of deviations in the results provided relative to the actual values. The error can be 0.001%, and 10%, or more. In this case, random and systematic deviations are distinguished. The random error of the measurement result is characterized by the fact that it does not obey a certain regularity. Conversely, systematic deviations from actual values differ in that they retain their values even with numerous repeated measurements.

Conclusion

Manufacturers of measuring instruments and highly specialized metrological equipment strive to develop more functional and at the same time affordable models. And this applies not only to professional equipment, but also household appliances. For example, current measurement can be carried out at home using a multimeter that records several parameters at the same time. The same can be said about devices working with readings of pressure, humidity and temperature, which are endowed with wide functionality and modern ergonomics. True, if the task is to register a specific value, then experts still recommend referring to special devices that work only with the target parameter. They, as a rule, have higher measuring accuracy, which is often crucial in assessing the performance of the equipment.