Many needlewomen want to develop their skills in applied creativity, trying and studying new types of crafts. Many will be interested in working with polymer clay. It is quite easy to use, and products from it look very beautiful and unusual. But getting started with this material, you need to know that it must be varnished. This article will tell you how to choose the right varnish, how to apply and dry it.

What is polymer clay

Polymer clay is a material that is used to create small figures and products, such as crafts and decorations, and is also often used in modeling. It hardens if it is heated to a certain temperature, most often to 100 - 130 degrees Celsius. In its structure and appearance, it strongly resembles plasticine, familiar to everyone. It differs from plasticine in its ability to harden. It can have different colors. Finished products are often varnished from polymer clay.

Composition

Polymer clay has a fairly simple composition. It is made on the basis of PVC, with the addition of one or many plasticizers in liquid form. The substance is obtained in a transparent color. For coloring, in any colors, koalin, white porcelain or other types of pigments can be added. Sometimes it is required to obtain a substance of metallic or pearlescent color. In this case, mica is used as a pigment.

In addition to solid clay, some manufacturers produce a liquid version of the polymer clay in the form of a gel. The properties remain the same - when heated, the gel hardens.

Where is polymer clay used?

The scope of this material is very wide. Polymer clay is very popular in needlework. From it you can make not only various figurines and souvenirs, but also beautiful jewelry for sale or for yourself. In modeling, this material is used to create sculptures and layouts. Having a dense structure, clay serves for a long time and does not deform. Often used in creating decor and interior items, designer dolls, Christmas toys, as well as bouquets. Initially, this material was created specifically for the manufacture of dolls.

Types of varnish

Any polymer clay should be varnished. The following main types of varnish for polymer clay are distinguished:

- Glossy. Shines, often gives the effect of the appearance of many bubbles. It is more suitable for covering small products; it does not fit well on large ones. Most often used for varnishing various beads. The glossy polymer clay varnish gives them a beautiful and even glass shine. When hit gives strong chips.

- Matt It does not have shine. The product rests more evenly and accurately than glossy. Wear resistant. Among the shortcomings, it can be distinguished that the matt varnish for polymer clay emphasizes all the shortcomings of the product. Some irregularities of crafts before coating with matte varnish are not visible, and after coating they become pronounced. It does not crack, when falling, it most often retains its previous appearance.

- Acrylic. The most common acrylic varnish for polymer clay is often used. It is this varnish that is used in needlework and crafts. In terms of wear resistance it is inferior to matte, but it looks dignified and easy to apply.

- Specialized. Specialized are varnishes that are made by the manufacturers of polymer plastics themselves. They may cost more, but their composition is precisely matched to a specific material.

Gloss classification of varnish

Here, varnishes can be divided into four types:

- Glossy (have a characteristic luster, create a "glass" look).

- Semi-gloss (not so shiny).

- Matte (have no shine).

- Semi-matt (reminiscent of a mixture of matte and glossy).

Most often, with respect to polymer clay, matte varnishes are used. They do not distort the color of the material; they better convey the structure of clay. Matte varnish for polymer clay also has a denser structure, protecting the product from damage.

Rating of the best varnish

Many beginners who have just begun their acquaintance with a material such as polymer clay often wonder: what kind of varnish for polymer clay to buy, which is better and more practical? There is simply no concrete answer to this question. You can only compare the price characteristics and read reviews of those people who have long tried various means in this area. The main favorites have long stood out on the varnish market, including:

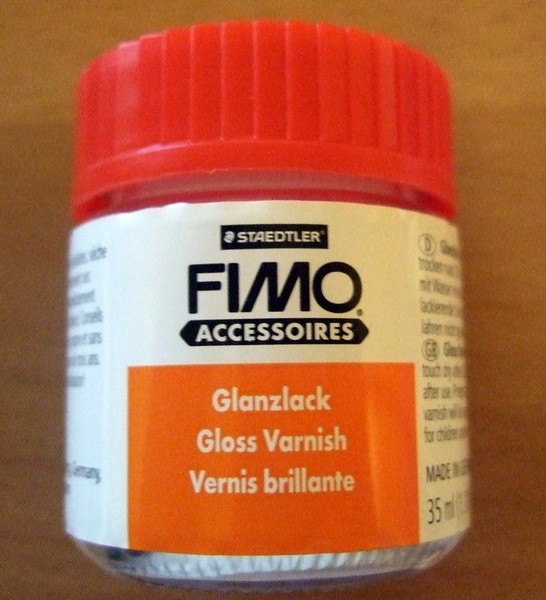

1. Varnishes from the famous brand "FIMO". This company has a long history. In 1930, in Germany, Fifi Rebinder released polymer clay. Her creator appropriated the name "Fifi Mosaics." Fifi needed this material to make something like porcelain dolls, only less fragile. After 34 years, Rebinder sold the clay formula. The buyer was Eberhard Faber. He began large-scale production of varnish for polymer clay "FIMO" and the clay itself. For many years, the company not only did not cease to exist on the world market, but also began the production of additional tools for polymer clay. Including a wide variety of varnishes. The main options here will be varnishes for polymer clay on a water or mineral basis. But in recent times, mineral-based varnishes have ceased to be produced. Among the main disadvantages of the FIMO brand are the following: the appearance of yellowness on the product, cracking and chips of varnish, as well as the fragility of the coating. The price varies from 250 to 400 rubles, depending on the volume and type of varnish.

2. The next well-known company can be called POLYFORM PRODUCTS CO. She produces two good varnishes: Sculpey Glossy Glaze and Satin Glaze. The first is glossy and gives the product shine, the second is matte and does not give shine. Among the advantages distinguish: resistance of varnish, good protection against scratches and chips. These varnishes can be applied even before you put the clay on the bake. This is also an important plus. It is also possible to apply POLYFORM PRODUCTS CO varnish for polymer clay with a very thin layer (due to the fact that it is very liquid). Application by a large number of layers contributes to the creation of the effect of "glass". Since the varnish adheres very well to the tree, it is categorically not recommended to try to trim it on the product with a toothpick or any wooden object. The price of Sculpey Glossy Glaze varies from 400 to 500 rubles, and Satin Glaze from 400 to 450 rubles per 30 ml.

3. Among other good companies for the production of polymer clay varnish, VIVA.Schmuck is also distinguished. She produces Lack Viva Decor. Differs in density, even more sticks to a tree. It is better to use with polymer clay of the same company, because this varnish does not fit so well on other materials. Among the minuses: poor compatibility with materials from other companies, poor durability. Among the advantages: it forms a beautiful film, emphasizes the appearance of the product. The price is approximately 500 - 600 rubles

4. Further it is worth noting the construction companies. Varathane and its product VARATHANE CRYSTAL CLEAR WATERBONE DIAMOND WOOD FINISH stand out here. The product should be called that way, because there are many other varieties of funds for coverage from the same company. Varieties: matte, glossy, semi-matt. It is created on a water basis. Experienced craftsmen use this particular varnish, which has long been tested by time. The price will be quite high, but only due to the fact that the product is sold in large volumes, as it is considered to be construction.

5. "Tikkurila" - produces two good products - KIVA and ASSA. These varnishes are acrylic on a polyurethane basis. They are sold in large volumes, so the price will be quite bitten - 6500 rubles for 3 liters.

6. Decoupage varnish IDEA from MAIMERI. It is made in Italy. It has a water base, lays well and protects from scratches for a long time. The price will be 700 rubles for 75 ml. Such a varnish for products made of polymer clay is more convenient in terms of its ratio of price and volume.

It should be noted that construction varnishes are not so easy to find even in online stores. They are not common, and sometimes you need to try hard to order or buy a similar tool. Among the minuses of all construction varnishes, only their large volume can be distinguished. For applied art, they will be very uncomfortable, as they will simply dry out while you try to make a wagon of products to cover them with all 3 liters of building varnish. And which polymer clay varnish is better, is up to everyone to decide. You can follow the advice of those who already had experience with varnishes for polymer clay. Feedback on such matters is very helpful.

Terms of use

After you have decided which varnish to cover polymer clay with, you need to figure out how to do it competently. After all, few people want to spoil a beautiful product due to improper coverage. Despite the fact that each tool is accompanied by a special instruction that explains the rules of application and indicates the drying time of the varnish, there are a number of important points that every beginner needs to know. Here is some of them:

- When applying varnish, give the layers enough time to dry. It’s better to wait longer than to redo the work completely.

- Do not use wooden objects (toothpicks or matches) to correct bumps in the varnish layer. Many products can adhere very well to wooden surfaces.

- Regardless of the polymer clay you choose, varnishing is considered a necessary part of the manufacture of the product. Let your material cost at least 3000 rubles, it will still need to be protected from chips and scratches. So the product will live much longer, and it will feel more pleasant in the hands.

- Close the varnish jar tightly. So it will not dry out and will last longer.

- Do not buy large construction cans with varnish, even if they are very good, but you are going to make only a couple of products. Most of the funds will remain unused, and you just spend the money. It’s better to buy a small one. Construction varnishes are almost always sold in large volumes, and it is not always possible to use it in applied art on time.

- The drying time of the varnish must be watched individually on each package.

- To achieve the best effect, it is better to apply the varnish to the finished product not with a brush, but dip it directly into the liquid. Full drying occurs after a week. This week, you can touch the craft around 48 hours later, and then pick it up, just do not wet it with water.

Main mistakes

When working with polymer clay, attention to detail is very important, especially when coating a product with varnish. Often beginners make common mistakes, the result of which can simply discourage any desire for further work. To avoid such difficulties, it is better to familiarize yourself with the list of the main mistakes when coating polymer clay with varnish:

- Trying to pour clay with a lot of varnish. Beginners think that this way their jewelry or souvenir will last longer and will look prettier. But this is not so. The thick layer of varnish dries for a long time and does not always dry to the end.

- The idea that cheap varnish is bad varnish. This is not true. The price depends on its type. From whether it is glossy or matte. From the volume and many other reasons. You should not buy what is more expensive if you really do not even have experience in this craft.

- Attempts to fix the varnish when it has already begun to dry. When dried, the varnish forms a thin film, which, when you try to move it, will simply be removed and will not be able to lie back exactly.

- Do not use regular nail polish. If it is transparent and lays well on nails, this does not mean that the same thing will happen on your clay product.

- You do not need to buy ordinary acrylic paints, which are sold in every needlework store. They will not be a good option for this material.

- It is advisable to apply at least 2-3 layers of varnish. Only not thick and with a gap for sufficient drying.

- After polishing the craft, you need to remove all remaining dust and debris from it. Otherwise, all this dirt will remain under a layer of varnish and will stick out, spoiling the entire appearance of even the most successful product.

- If a lot of such a substance as a plasticizer was added in polymer clay, then after applying the varnish a noticeable greasy film may remain. How to avoid this? Before applying varnish, you need to wash the product with a sponge with detergent or wipe it with a cloth soaked in a solution of alcohol. From dirty hands that come in contact with the material, such a film may also appear.

- The cause of cleavage may be that the very first layer is not sufficiently dry. Instead of 10 to 30 minutes, it is better to give the product an hour of drying time. And so with each layer. No need to think that the second or third layer will be able to close the bumps in the first layer. The first is the most basic, if it cracks, then all other layers of varnish crack.

- If an unsuccessful varnish is bought, it may begin to stick. Predicting this is quite difficult, so you need to know how to fix it. One of the effective solutions to this problem is repeated baking for 10 - 15 minutes at a temperature of 100 degrees. If this option does not help, just wipe off the varnish layer with a cotton pad dipped in acetone and apply a new layer of another fixing agent.

Price

The cheapest varnish for products made of polymer clay can be bought for 200 rubles. The volume will be small, but it will be enough for 2 - 3 products. You need to understand that the larger the volume of the jar of varnish, the higher its price. If you are just starting work in this area, it is better not to overpay or buy large cans of varnish.

Reviews of the masters

The easiest way to understand the essence of the work and learn something useful is to read the reviews of those who have long been practicing in any industry. In our case, this is information about varnishes for polymer clay. Reviews about them are presented below:

- It is generally better not to take nail polish in the case of polymer clay. Over time, it can simply dissolve the material, just like regular acrylic paint. It is better to buy a special tool. In general, there is no difference what kind of varnish to buy, if only not for nails.

- Glossy water-based varnish holds well, despite negative reviews. Appearance keeps beautiful, does not crack. And the effect of glass is so excellent!