The 21st century is the century of radio electronics, the atom, space exploration and ultrasound. The science of ultrasound is relatively young these days. At the end of the 19th century, P. N. Lebedev, a Russian physiologist, conducted his first research. After this, many prominent scientists began to engage in ultrasound.

What is ultrasound?

Ultrasound is a wave-like oscillatory motion propagating by particles of a medium. It has its own characteristics, which differs from the sounds of the audible range. It is relatively easy to obtain directional radiation in the ultrasonic range. In addition, it focuses well, and as a result of this, the intensity of the performed oscillations increases. When propagating in solids, liquids and gases, ultrasound gives rise to interesting phenomena that have found practical application in many fields of technology and science. This is what ultrasound is, whose role in various areas of life is very great today.

The role of ultrasound in science and practice

Ultrasound in recent years began to play an increasingly important role in scientific research. Experimental and theoretical studies in the field of acoustic flows and ultrasonic cavitation have been successfully carried out, which allowed scientists to develop technological processes that occur when exposed to ultrasound in the liquid phase. It is a powerful method for studying various phenomena in a field of knowledge such as physics. Ultrasound is used, for example, in the physics of semiconductors and solids. Today, a separate line of chemistry is being formed, called "ultrasonic chemistry." Its application allows you to accelerate many chemical-technological processes. Molecular acoustics was also born, a new branch of acoustics that studies the molecular interaction of sound waves with matter . New areas of application of ultrasound have appeared: holography, introscopy, acoustoelectronics, ultrasound phase metering, quantum acoustics.

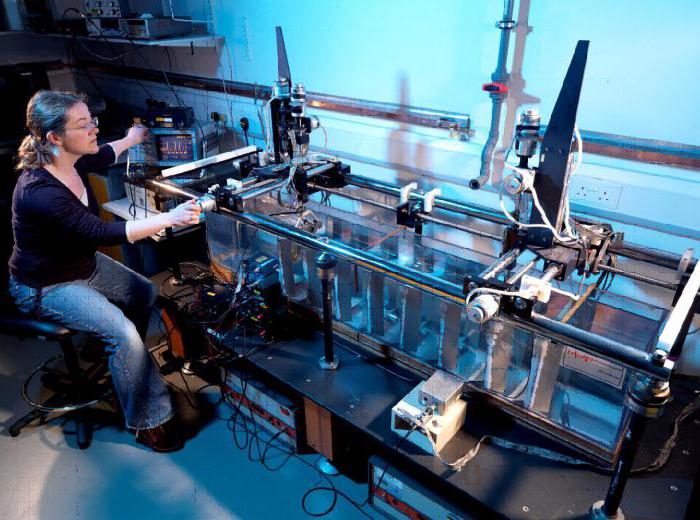

In addition to experimental and theoretical work in this area, today a lot of practical work has been carried out. Special and universal ultrasonic machines, installations that operate under increased static pressure, etc. have been developed. Ultrasonic automatic installations included in production lines have been introduced into production, which can significantly increase labor productivity.

More on ultrasound

We will tell you more about what is ultrasound. We have already said that these are elastic waves and vibrations. The frequency of ultrasound is more than 15-20 kHz. The subjective properties of our hearing is determined by the lower limit of ultrasonic frequencies, which separates it from the frequency of audible sound. This boundary is thus conditional, and each of us defines in different ways what ultrasound is. The upper boundary is indicated by elastic waves, their physical nature. They propagate only in the material medium, that is, the wavelength should be significantly longer than the mean free path of the molecules present in the gas or the interatomic distances in solids and liquids. Under normal pressure in gases, the upper limit of ultrasonic frequencies is 10 9 Hz, and for solids and liquids - 10 12 -10 13 Hz.

Sources of Ultrasound

Ultrasound is found in nature both as a component of many natural noises (waterfall, wind, rain, pebbles, rolled by the surf, as well as in sounds accompanying lightning discharges, etc.), and as an integral part of the animal world. Some species of animals use it to orient themselves in space, to detect obstacles. It is also known that dolphins use ultrasound in nature (mainly frequencies from 80 to 100 kHz). In this case, the power of the radar signals emitted by them can be very large. It is known that dolphins are able to detect schools of fish located at a distance of one kilometer from them.

Ultrasound emitters (sources) are divided into 2 large groups. The first is generators in which the oscillations are excited due to the presence of obstacles in them that are installed in the path of constant flow - a stream of liquid or gas. The second group, in which ultrasound sources can be combined, is electro-acoustic transducers, which turn the given fluctuations of current or electric voltage into mechanical vibrations made by a solid body, emitting acoustic waves into the environment.

Ultrasound receivers

At medium and low frequencies , ultrasonic transducers are most often piezoelectric-type ultrasound receivers. They can reproduce the form of the received acoustic signal, presented as a temporal dependence of sound pressure. Devices can be either broadband or resonant - depending on what application conditions they are intended for. Thermal detectors are used to obtain the characteristics of the sound field averaged over time. They are thermistors or thermocouples coated with sound absorbing material. Sound pressure and intensity can also be estimated by optical methods, such as light diffraction by ultrasound.

Where is ultrasound used?

There are many areas of its application, while using various features of ultrasound. These spheres can be divided arbitrarily into three directions. The first of them is associated with the receipt of various information through ultrasonic waves. The second direction is its active effect on the substance. And the third is related to the transmission and processing of signals. Ultrasound of a certain frequency range is used in each case. We will only talk about some of the many areas in which it has found its application.

Ultrasonic Cleaning

The quality of such cleaning cannot be compared with other methods. When rinsing parts, for example, up to 80% of dirt remains on their surface, about 55% during vibration cleaning, about 20% during manual cleaning, and when ultrasonic, no more than 0.5% dirt remains. Parts that have a complex shape can only be cleaned well with ultrasound. An important advantage of its use is high productivity, as well as low costs of physical labor. Moreover, it is possible to replace expensive and flammable organic solvents with cheap and safe aqueous solutions, apply liquid freon, etc.

A serious problem is air pollution by soot, smoke, dust, metal oxides, etc. An ultrasonic method can be used to purify air and gas in gas outlets, regardless of humidity and temperature. If the ultrasonic emitter is placed in a dust settling chamber, its effectiveness will increase by a factor of hundreds. What is the essence of such a purification? Dust particles randomly moving in the air hit stronger and more often against each other under the influence of ultrasonic vibrations. At the same time, their size increases due to the fact that they merge. Coagulation is the process of particle enlargement. Special filters capture their weighted and enlarged aggregations.

Machining of brittle and superhard materials

If an abrasive material is introduced between the workpiece and the working surface of the tool using ultrasound , then the particles of abrasive during the operation of the emitter will affect the surface of this part. At the same time, the material is destroyed and removed, being subjected to processing under the action of many directed microshocks. The processing kinematics consists of the main movement — cutting, that is, longitudinal vibrations made by the tool, and the auxiliary — the feed motion, which the apparatus performs.

Ultrasound can do various jobs. For abrasive grains, the source of energy is longitudinal vibrations. They destroy the processed material. The feed movement (auxiliary) can be circular, transverse and longitudinal. Ultrasonic processing is more accurate. Depending on the granularity of the abrasive, it ranges from 50 to 1 microns. Using tools of different shapes, you can make not only holes, but also complex cutouts, curved axes, engrave, grind, fabricate dies and even drill a diamond. The materials used as an abrasive are corundum, diamond, quartz sand, flint.

Ultrasound in Electronics

Ultrasound in technology is often used in the field of electronics. In this area, it is often necessary to delay an electrical signal relative to some other. Scientists have found a good solution by proposing the use of ultrasonic delay lines (abbreviated as LZ). Their action is based on the fact that electrical impulses are converted into ultrasonic mechanical vibrations. How does this happen? The fact is that the speed of ultrasound is significantly less than that developed by electromagnetic oscillations. The voltage pulse after the reverse conversion into electrical mechanical vibrations will be delayed at the output of the line relative to the input pulse.

Piezoelectric and magnetostrictive transducers are used to convert electrical vibrations into mechanical ones and vice versa. LZ, respectively, are divided into piezoelectric and magnetostrictive.

Ultrasound in medicine

Various types of ultrasound are used to affect living organisms. In medical practice, its use is now very popular. It is based on the effects that occur in biological tissues when ultrasound passes through them. The waves cause oscillations of the particles of the medium, which creates a kind of micromassage of tissues. And the absorption of ultrasound leads to their local heating. At the same time, certain physical and chemical transformations occur in biological media. These phenomena in the case of moderate sound intensity do not cause irreversible damage. They only improve metabolism, and therefore contribute to the vital functions of the organism subject to them. Such phenomena are used in ultrasound therapy.

Ultrasound in surgery

Cavitation and strong heating at high intensities lead to tissue destruction. This effect is used today in surgery. Focal ultrasound is used for surgical operations, which allows local destruction in the deepest structures (for example, the brain), without damaging the surrounding environment. In surgery, ultrasound instruments are also used, in which the working end has the form of a file, a scalpel, and a needle. The oscillations imposed on them give new qualities to these devices. The required force is significantly reduced, therefore, the injuries of the operation are reduced. In addition, an analgesic and hemostatic effect is manifested. Exposure to a blunt instrument using ultrasound is used to destroy some types of neoplasms that have appeared in the body.

The impact on biological tissues is carried out to destroy microorganisms and is used in the sterilization processes of drugs and medical instruments.

The study of internal organs

This is mainly a study of the abdominal cavity. For this purpose, a special apparatus is used. Ultrasound can be used to find and recognize various tissue abnormalities and anatomical structures. The task is often this: there is a suspicion of a malignant mass and it is required to distinguish it from a benign or infectious mass.

Ultrasound is useful in examining the liver and for solving other problems, which include the detection of obstruction and diseases of the bile ducts, as well as the study of the gallbladder to detect the presence of stones and other pathologies. In addition, a study of cirrhosis and other diffuse benign liver diseases can be used.

In the field of gynecology, mainly in the analysis of the ovaries and uterus, the use of ultrasound has for a long time been the main direction in which it is carried out especially successfully. Often, differentiation of benign and malignant formations is also needed here, which usually requires the best contrast and spatial resolution. Similar conclusions can be useful in the study of many other internal organs.

The use of ultrasound in dentistry

Ultrasound has also found its application in dentistry, where it is used to remove tartar. It allows you to quickly, bloodlessly and painlessly remove plaque and stone. In this case, the oral mucosa is not injured, and the "pockets" of the cavity are disinfected. Instead of pain, the patient experiences a feeling of warmth.