If you want to make a 3D scanner yourself, first of all, find a webcam. If you have one, the cost of the entire project will cost 40-50 dollars. In recent years, 3D desktop scanning has made big leaps, but it still has big limitations. The hardware of the equipment is built on the basis of a certain volume and scan resolution. You can get good results only if your subject meets the requirements and resolution.

The principle of shooting in surround mode

Photogrammetry uses a set of ordinary two-dimensional photographs taken from all sides around the object. If a point on an object can be seen in at least three pictures, its location can be triangulated and measured in three dimensions. By identifying and calculating the location of thousands or even millions of points, the software can create extremely accurate reproduction.

Unlike a hardware scanner, this process has no restrictions on size or resolution. If you can take a picture of an object, you can scan it:

- The limiting factor in photogrammetry is the quality of photographs and, therefore, the skill of the photographer.

- Photos should be clearly visible and clearly focused.

- They should also be located around the object so that each part is covered.

Without a 3D scanner, you can make a three-dimensional image of only large objects. Small items cannot be scanned. To understand this in more detail, we will analyze the concept of photogrammetry.

What is photogrammetry and how does it affect the display of objects?

Photogrammetry is the science of taking measurements from photographs, especially to restore the exact position of surface points. It can also be used to restore the trajectories of the designated reference points on any moving object, its components and in close proximity to the environment.

In short, it makes it possible to create a three-dimensional grid of several photographs, comparing the similarities between the images and triangulating them in three-dimensional space.

Photogrammetry has been around for some time, but only when Autodesk joined its beta program Memento did everything work stably. Memento was renamed ReMake when it left the beta phase. Sounds like magic, right? Well, this is not magic, this is reality. Now anyone can do 3D scanning without spending hundreds on a scanner. Even affordable open source 3D scanners require quite a bit of knowledge to get them to work properly. Using photogrammetry, anyone can get what he wants.

Turntable - the second step in creating a scanner

All you need to create a 3D scanner with your own hands is your smartphone, the supplied headphones and a player. Here's how it works: you turn the knob, and for every full revolution of the turntable, the phone’s camera fires 50 times from the headphone volume.

Simply! Transfer photos to your computer, and then use Autodesk ReMake to work wonders. This is surprising, but it not only creates a mesh well, but also provides tools for adjusting the mesh, repairing holes, aligning, preparing for 3D printing or serves as a system form as a 3D resource for games or visualization!

Well, given that Apple has removed the headphone jack for iPhone 7 and above, an updated version of the scanner will be used. It is based on the trigger principle for a Bluetooth camera. This will replace the need for a headphone jack.

- High-quality photogrammetric scanning requires high-quality photographs of the subject from all sides.

- The easiest approach for scanning small things is to rotate the subject while photographing.

- For this, the scanner uses a stepper motor controlled by the Arduino board.

- The stepper turns the object a fixed amount, and then the infrared LED turns off a hell of a cunning series of flashes that mimic the camera’s wireless remote control.

An LCD screen with a set of buttons allows the user to control the Arduino. Using the buttons, the user can select the number of shots to be taken per revolution. A self-made high-quality 3D scanner can work in automatic mode, where it takes a picture, advances the stepper motor and repeats it until it completes a full revolution.

There is also a manual mode in which each press of the button takes a picture, moves the jog dial and waits. This is useful for scanning parts. The 3D scanner focuses on the frame framing the image.

Additional software

When the photogrammetry software detects a function in a photograph, it tries to find this function in other images and records the location in all the pictures that appear.

- If the object is part of a rotating object, we get good data.

- If the detected function is in the background and does not move while the rest of the object is scanned, this can lead to a breakdown of the space-time continuum, at least with regard to your software.

There are two solutions:

- One of them is moving the camera around the subject so that the background remains synchronized with the movement. This is good for large objects, but much more difficult to automate the process.

- A simpler solution is to leave the background without features. It is easier to do for small objects. Add the right lighting to it, and you're on your way to faceless backgrounds.

Another tip is to overexpose your images with a stop or two. This allows you to capture more detail in the shadow of the object, while simultaneously separating the background, so all remaining background objects disappear in a sparkling white color.

- Arduino It has contacts that are not covered by the LCD screen, which makes connecting easier.

- SainSmart 1602 LCD Shield, which has a display and several buttons to control the scanner.

- Stepper motor driver (Easy Driver).

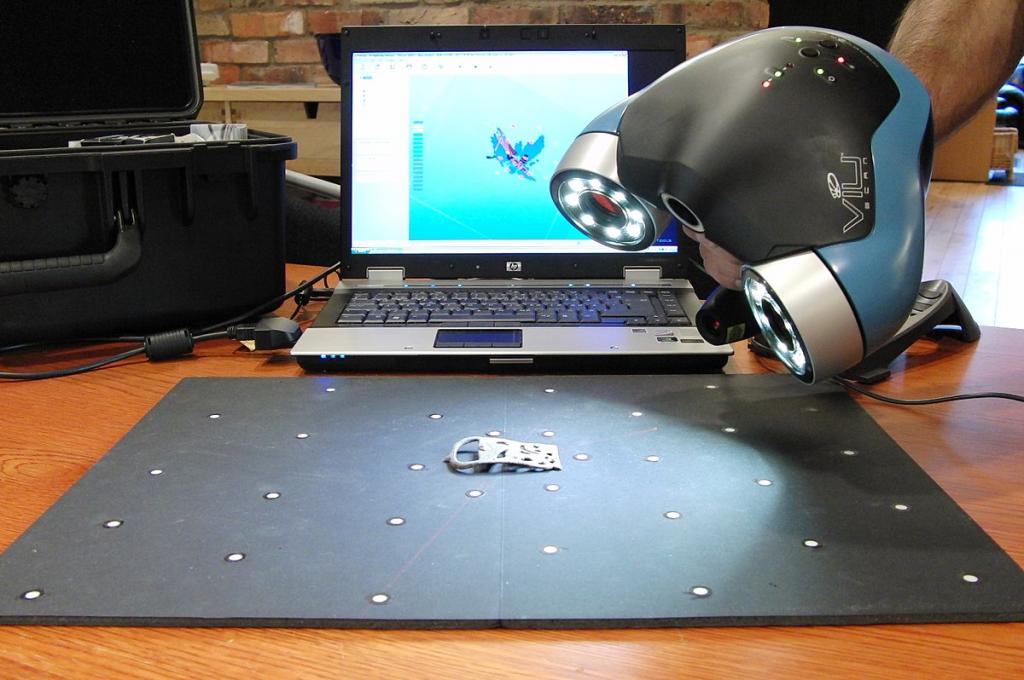

The NEMA 17 stepper motor will rotate the scan object. With a large stepper motor (with the appropriate driver and power supply), this self-made 3D scanner of high quality could increase the scale of the scan. 950 nm IR LED triggers the camera. Some popular models of handheld 3D scanners are based on this principle. With your own hands, you can repeat the building process. We offer several options to choose from.

Tony Buzer's Spinscan: The Basis of All Scanners

In 2011, the genius of 3D printing, Tony Buiser, released Spinscan. This is a homemade open source 3D scanner based on a laser and digital camera. Later, MakerBot used ideas from Spinscan to create a closed-source Digitizer scanner.

Fabscan

FabScan began as a graduation project and has since been accepted by a small community that continues to work to improve its capabilities. FabScan works like many other laser scanners, but it has an integrated housing that helps level out light levels to prevent distortion during scanning.

Virtucube

An alternative method for laser scanners is a structured light scanner. Using a pico projector instead of a laser, VirtuCube can be easily created with several printed parts and basic electronics. This whole system can be placed in a cardboard box so that other light sources do not cause printing errors.

Already released two new interesting open source laser scanners: The BQ Cyclop and Murobo Atlas.

BQ - Laser Scanning System

Spanish consumer electronics company BQ has announced the Cyclop 3D scanner at CES. Cyclop uses two laser line levels, a standard USB webcam and an Arduino user controller from BQ. BQ has written its own scanning application called Horus. While the reports say that Cyclop is not yet available, BQ says it will be later this year.

Atlas - a developed project requiring improvements

A 3D scanner describing how it works from Murobo is currently seeking funds on Kickstarter. Like Spinscan, Digitizer and Cyclop, Atlas uses laser line modules and a webcam to scan an object on a rotating platform. Atlas replaces the Arduino Raspberry Pi to combine control and capture into the device. Like Cyclop, the creator of Atlas promises to be an open source project. $ 129 kits sold out, but some were priced at $ 149 and $ 209.

In 2019, the company seeks to release a 3D scanner created from a smartphone, which will not only display background visibility, but also design focus when capturing an image. In America, DIY innovations are amazing. If you don’t know how to make a 3D scanner, use the incomplete version of Atlas. There is quite understandable functionality, and developers only need to flash the device and ensure the operation of those functions that you want to see as a result.

CowTech Ciclop: New All-In-One Model

The price reaches $ 160 (depending on whether you print 3D parts or not). The company is based in the USA. The resolution of the finished image reaches 0.5 mm. Maximum scan volume: 200 × 200 × 205 mm. BQ formed the basis for the DIY 3D scanner kit for a 3D printer. With your own hands, you can refine the version of the model to create images in four-dimensional space.

CowTech Engineering has used funds led by BQ, giving unique value to the updated model. Opportunities have appeared:

- environmental review

- capture background

- display lenses inverted style.

True to the open source movement, Cowtech launched a Kickstarter campaign to raise money to launch the original version of the Ciclop CowTech. The team set a high goal - to raise $ 10,000, but was greeted with surprise and enthusiasm when the community was able to raise $ 183,000. The 3D scanner kit from the CowTech Ciclop DIY camera and phone was born.

So what is the difference between the CowTech and BQ DIY versions?

CowTech Ciclop still uses Horus 3D software, as it is a fantastic store for 3D object scanning. The differences, however, lie in a slightly different design, the development of which the team spent several days so that the details could be printed in 3D on any FDM 3D printer.

These blanks can be used to develop devices with your own hands. The 3D scanners and printers of this company have only a small assembly volume, so CowTech has developed parts that can be printed on any printer with an assembly volume of 115 × 110 × 65 mm, which is found in almost all 3D printers.

Ciclop by CowTech:

- There are adjustable laser holders here.

- CowTech DIY uses acrylic laser cutting.

BQ Ciclop:

- Models use threaded rods.

- Laser cutting of acrylic is absent.

There is nothing to worry about, and the scanners still look pretty similar, but CowTech intended only to improve the existing design, and not to reform it. CowTech Sells Scan-Ready Ciclop for $ 159 On Its Website. All in all, this is a great cheap DIY 3D scanner, very effective for laser triangulation 3D scanning.

Rotary machines and tables for creating scanners

- The mobile phone is equipped with DIY 3D-scanner technology: photogrammetry - there is a technological feature.

- Price: Free printing on your own (although materials will cost about $ 30).

- This 3D scanner with your own hands will be quite simple to create. Dave Clark, a British manufacturer, even before the start of sales, made sure that the models could be disassembled. Spare parts will be used to create other scanners.

This is due to the fact that it is based on photogrammetry, and not on laser triangulation and is compatible with your smartphone! You can download a file for 3D printing to sync devices.

With your own hands, a 3D scanner can be made from improvised means. You only need to trust the creators of DIY 3D. A simple device instantly turns your iPhone or Android into a 3D scanner by connecting it to this player. Then, using headphones and a telephone camera, he takes more than 50 photographs of the object that will be scanned as the turntable rotates.

After you take these images, you can upload them to a program such as Autodesk ReCap to turn photos into a full-fledged 3D file.

All in all, this is a fantastic creative project and a great DIY 3D scanner for people on a budget.

Microsoft Kinect 3D Scanner

Its cost is even lower - only $ 99 (however, no longer for sale, although Kinect V2 is still available with the Xbox One). Company slogan: "Do it yourself 3D scanner from Kinekt and surprise your friends.

While Microsoft has responded to demand by creating its own 3D Scan app for the Kinect scanner, there are a number of third-party options that might be preferable. These include:

- Skanect, made by Occupital, which also sells a frame sensor.

- ReconstructMe. It provides a set of tools that allow you to perform 3D scanning for less than $ 100.

The results are not fantastic, but for the price they are quite acceptable. It has been proven that it is inferior to the traditional options for protogrammetry in quality, especially in small details, for example, on small models such as shark teeth. However, for beginner 3D scanners, this is a fantastic entry-level product, especially since you may already have one for the Xbox 360.

Before creating a scanner

There are many cameras that you can use. Of course, in order to know how to make a 3D scanner from your phone yourself, you need to calculate what you need for this. If you plan to use the Pi Scan to control cameras, then you should use the Canon PowerShot ELPH 160. But if you use some other setting, here are some general recommendations for choosing cameras:

- How many megapixels do you need? Measure the items you are about to scan. Strive for the largest average size (do not select the largest emissions). For example, most textbooks are 22.86 × 27.94 cm in size. Now multiply this size by the PPI (pixels per centimeter) that you intend to capture. 300 is a safe minimum, although you won't go wrong if you capture more. So, in our example - 9 × 300 = 2700. 11 × 300 = 3300. We need an image with a size of at least 2700 × 3300 = 8 910 000 pixels, or about 9 megapixels.

- What control do you need? If you simply scan one book or scan an object only for its informational content (as opposed to trying to capture the actual appearance), you do not need very good pictures. If the lighting or camera settings change from shot to shot, you will still get a quality result.

- Shutter Speed - ISO White Aperture Balance.

- Flash on / off Any custom image processing (sharpening, improving color, etc.).

- Focus (ideally the ability to lock focus).

- Exposure compensation.

- Image magnification - most SLR cameras allow all this kind of control; for compact cameras, only Canon Powershot cameras supporting CHDK. They allow you to control all of these parameters.

Much depends on the budget. Scanners are sold at the same price as cameras. If you want to do everything yourself, then the budget is limited. Pay attention to the affordable segment of the optics and spare parts market.

- The first difficulty encountered in creating a three-dimensional laser scanner is finding a rotating platform. At the same time, it needs to be controlled only using MatLab. Instead of spending a lot of money or time, you can buy a 28BYJ-48-5V stepper motor with a ULN2003 drive test module board.

- Next, glue the platform to the shaft of the stepper motor and place it in the groove inside the holder. The platform should be on the same level with “marble”, but keep in mind that the cheaper it is, the more incompatible are the diameters that can make things uneven.

- If you have a method for obtaining precise rotation that can be controlled in Mat Lab, set up the camera at any distance and height, as well as the laser line to the left or right of the camera and from the turntable. The angle of the laser should be optimal to cover most of the turntable, but nothing should be accurate, we will handle the difference in the scale of the model in the code.

- The most important part for proper operation is camera calibration. Using the MatLab computer vision toolkit, you can get the exact focal length and optical center of the camera with an accuracy of 0.14 pixels.

Keep in mind that changing the resolution of the camera will change the values of the calibration process. The main values that we are looking for are the focal length, measured in pixel units, and the pixel coordinates of the optical center of the image plane.

Most cheap compact cameras do not have a software interface. They can only be controlled by manual or mechanical starting. But a team of volunteers has developed software that allows you to remotely control and configure Canon compact cameras. This software is called CHDK.

- CHDK is downloaded to the SD card, which is then inserted into the camera.

- When the camera starts up, CHDK starts up automatically.

- Since the CHDK never makes permanent changes to the camera, you can always simply remove the special CHDK SD card for normal camera operation.

CHDK is an important prerequisite for the software controllers listed below. The controllers work on a PC or Raspberry Pi and interact with the CHDK software running on cameras via USB. When using other types of cheap cameras, the only control option is any mechanical or manual start-up through installers, as shown above.