The Stirling engine, the operating principle of which is qualitatively different from the usual for all ICE, once constituted a worthy competition to the latter. However, for some time they forgot about him. How this motor is used today, what is the principle of its operation (in the article you can also find drawings of the Stirling engine, clearly demonstrating its operation), and what are the prospects for future use, read below.

History

In 1816, Robert Stirling patented a heat engine in Scotland , named today in honor of its inventor. The first engines of hot air were invented before him. But Stirling added a cleaner to the device, which in the technical literature is called a regenerator, or heat exchanger. Thanks to him, the motor performance increased while keeping the unit warm.

The engine was recognized as the most durable steam engine available at that time, since it had never exploded. Before him, on other engines, such a problem arose often. Despite the rapid success, at the beginning of the twentieth century its development was abandoned, as it became less economical compared to other internal combustion engines and electric motors that appeared at that time. However, Stirling still continued to be used in some industries.

External combustion engine

The principle of operation of all thermal motors is that to obtain gas in the expanded state requires greater mechanical effort than when compressing cold. To demonstrate this, you can conduct an experiment with two pots filled with cold and hot water, as well as a bottle. The latter is dipped in cold water, plugged with a cork, then transferred to hot. In this case, the gas in the bottle will begin to perform mechanical work and push out the cork. The first external combustion engine was completely based on this process. However, later the inventor realized that part of the heat can be used for heating. Thus, productivity has increased significantly. But even this did not help the engine become widespread.

Later Erickson, an engineer from Sweden, improved the design by proposing to cool and heat the gas at constant pressure instead of volume. As a result, many copies began to be used for work in mines, on ships and in printing houses. But for the crews, they were too heavy.

External combustion engines from Philips

Similar motors are of the following types:

- steam;

- steam turbine;

- Stirling.

The latter type was not developed due to the low reliability and the remaining not the highest indicators compared to other types of units that appeared. However, in 1938, Philips resumed operations. Engines began to serve for drive generators in non-electrified areas. In 1945, the engineers of the company found a reverse use for them: if you spin the shaft with an electric motor, then the cooling of the cylinder head reaches minus one hundred and ninety degrees Celsius. Then it was decided to use the improved Stirling engine in refrigeration units.

Principle of operation

The action of the motor is to work on thermodynamic cycles in which compression and expansion occur at different temperatures. At the same time, the flow control of the working fluid is realized due to the changing volume (or pressure, depending on the model). This is the principle of operation of most of these machines, which can have different functions and design schemes. Engines can be piston or rotary. Machines with their installations work as heat pumps, refrigerators, pressure generators and so on.

In addition, there are open-cycle motors where flow control is implemented through valves. They are called the engines of Erickson, in addition to the general name Stirling. In the internal combustion engine, useful work is carried out after preliminary air compression, fuel injection, heating the resulting mixture mixed with combustion and expansion.

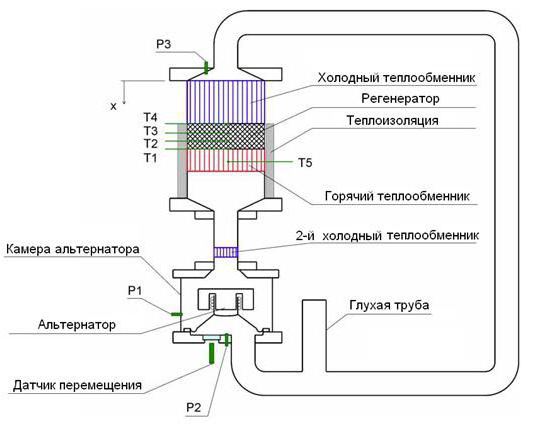

The Stirling engine has the same principle of operation: compression occurs at low temperature, and expansion at high temperature. But heating is carried out in different ways: heat is supplied through the cylinder wall from the outside. Therefore, he received the name of an external combustion engine. Stirling applied a periodic change in temperature with a displacement piston. The latter moves gas from one cavity of the cylinder to another. On the one hand, the temperature is constantly low, and on the other, high. When the piston moves up, the gas moves from hot to a cold cavity, and down - returns to hot. First, the gas gives a lot of heat to the refrigerator, and then it receives as much from the heater as it gave. Between the heater and the refrigerator, a regenerator is placed - a cavity filled with material to which gas gives off heat. In the reverse flow, the regenerator returns it.

The propellant system is connected to a working piston that compresses gas in the cold and allows it to expand in heat. Due to compression at a lower temperature, useful work occurs. The whole system goes through four cycles with intermittent movements. The crank mechanism provides continuity. Therefore, sharp boundaries between the stages of the cycle are not observed, and the efficiency of the Stirling engine does not decrease.

Given all of the above, the conclusion suggests itself that this engine is a piston machine with an external supply of heat, where the working fluid does not leave the enclosed space and is not replaced. Drawings of the Stirling engine well illustrate the device and its principle of operation.

Work details

The sun, electricity, nuclear energy or any other source of heat can supply energy to the Stirling engine. The principle of his body is the use of helium, hydrogen or air. An ideal cycle has a thermal maximum possible efficiency equal to thirty to forty percent. But with an effective regenerator, he will be able to work with higher efficiency. Regeneration, heating and cooling are provided by integrated oil-free heat exchangers. It should be noted that the engine needs very little lubrication. The average pressure in the cylinder is usually from 10 to 20 MPa. Therefore, an excellent sealing system and the possibility of oil entering the working cavities are required here.

Comparative characteristics

Most of today's engines of this kind use liquid fuel. At the same time, continuous pressure is easy to control, which helps to reduce emissions. The absence of valves ensures silent operation. Power and mass are comparable to turbocharged engines, and the specific power received at the output is equal to the diesel unit. Speed and torque are independent of each other.

The cost of producing an engine is much higher than that of an internal combustion engine. But during operation, the opposite indicator is obtained.

Benefits

Any model of the Stirling engine has many advantages:

- Efficiency in modern design can reach up to seventy percent.

- The engine does not have a high-voltage ignition system, camshaft and valves. It will not need to be regulated during the entire period of operation.

- In the Stirling there is no such explosion as in the ICE, which heavily loads the crankshaft, bearings and connecting rods.

- They do not have that effect when they say that the “engine has stalled”.

- Due to the simplicity of the device, it can be operated for a long time.

- It can work both on wood, and with nuclear and any other type of fuel.

- Combustion occurs outside the motor.

disadvantages

- The main disadvantage of the design is its material consumption.

- The working fluid needs to be cooled, due to which the dimensions are significantly increased.

- To obtain equal characteristics with ICE, it is necessary to use high pressure.

- Heat is supplied to the working fluid through the walls of heat exchangers with limited thermal conductivity.

- To change the engine power, change the volume of the buffer capacity, the average pressure of the working fluid, the phase angle between the displacer and the piston.

Application

Currently, the Stirling engine with a generator is used in many areas. It is a universal source of electrical energy in refrigerators, pumps, submarines and solar power stations. Thanks to the use of various types of fuel, there is the possibility of its widespread use.

Rebirth

These engines began to develop again thanks to Philips. In the mid-twentieth century, she signed a contract with General Motors. She led the development for the use of Stirling in space and underwater devices, on ships and cars. Following them, another company from Sweden, United Stirling, began to engage in their development, including the possible use in cars.

Today, the Stirling linear motor is used in installations of underwater, space and solar vehicles. Great interest in it is caused due to the relevance of issues of environmental degradation, as well as the fight against noise. In Canada and the USA, Germany and France, as well as Japan, there is an active search for the development and improvement of its use.

Future

The obvious advantages that the Stirling piston and rotary engine has , which consist in a long service life, the use of different fuels, noiselessness and low toxicity, make it very promising against the background of an internal combustion engine. However, given the fact that ICEs have been improved throughout the entire time, it cannot be easily biased. One way or another, just such an engine occupies a leading position today, and I do not intend to hand them over in the near future.