If you go to a modern mobile phone store and familiarize yourself with the products on offer, then the specifications for most devices on the windows will indicate: “Screen type - capacitive”. Those who often change mobile communication devices are familiar with this term, but what if they didn’t try to buy the latest, giving preference to proven solutions?

He can only be lost in conjecture: "Capacitive screen - what is it?"

Data entry technology

The principle of touch dialing is now used universally. For example, ATMs or machines for making various types of payments, on the panels of which there are a minimum of buttons, and the required numbers are entered by clicking on the corresponding image, can be found in almost every major store. Capacitive screens were first proposed back in the seventies, but they did not get distribution because of the lack of accuracy of recognition of the pressure zone and the complexity of implementation. But work to improve this solution continued.

Sensors in phones

When models of mobile communication devices with large screens appeared, the question of ergonomics immediately arose. Of course, it was possible to reduce the already small block of buttons, but this would affect the usability most negatively. Compromise solutions were used - the so-called "sliders", but this made the device too thick and made it less reliable due to the need to use a mechanical movable joint. Manufacturers began to search for a solution. And it was found. It turned out to be touch screens, by then significantly improved and ideal for phones.

Resisting pressing

The first models of such screens were made on a resistive basis. Due to a number of features, such sensors are used now. The structural-resistive screen consists of two completely transparent plates: the outer, on which the pressure is applied, is made flexible, and the inner, on the contrary, is rigid. The space between them is filled with transparent dielectric material. An electric current-conducting layer is deposited on both plates from the inside. It is specially connected by conductors to the controller, which constantly supplies low voltage to the layers. All this “sandwich” is fixed on the main display. When a person clicks on a portion of the screen, the plates touch at a certain point, current arises. Having determined the resistance values along two Cartesian axes, it is possible to find out exactly where exactly the pressing occurred with sufficient accuracy. These data are transferred to a working program, which further processes them.

Resistive sensors are inexpensive to manufacture, work great at low temperatures.

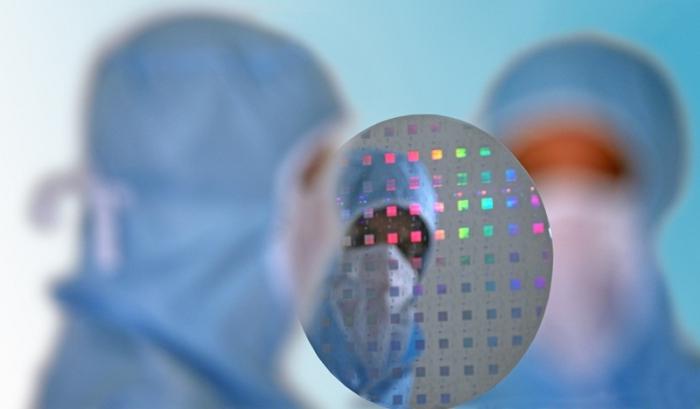

Capacitive screens

Capacitive sensors are much more advanced. Touchpads in laptops are a prime example of such solutions. On foreign sites, the characteristics of telephones with this technology indicate “Capacity”. In contrast to the resistive solution described above, here mechanical pressing is completely unimportant. In this case, the property of the human body to accumulate an electric charge is used, acting as a classical capacitor. Capacitive screens are more durable, have excellent "responsiveness." There are two ways to implement: surface and projection. In the first case, a transparent layer of conductive material is applied to the surface of the glass or plastic. It constantly contains the electric potential from the controller. It is enough to touch a point on the screen with your finger, as there is a leak from the battery into the human body. It can be easily determined, and the coordinates can be transferred to a working program. Projection capacitive screens work differently. Behind the outer glass of the display there is a grid of transparent sensor elements (they can be seen at a certain angle and lighting). If you touch the point, then in fact, a capacitor will be formed, one of the covers of which is the user's finger. The capacity in the circuit is determined by the controller and calculated. This solution allows you to implement multi-touch technology.