SMD (Surface Mounted Devices) is translated from English as “surface mount device”. SMD components are ten times smaller in size and weight than traditional parts, due to this a higher density of their installation on the printed circuit boards of devices is achieved. Nowadays, electronics is developing at a tremendous pace, one of the directions is the reduction in the overall dimensions and weight of devices. SMD components - due to their size, cheapness, and high quality - have become enormous and are increasingly replacing classic elements with wire leads.

The photo below shows the SMD resistors located on the circuit board.

You can see that, due to the small size of the elements, a high density of installation is achieved. Ordinary parts are inserted into special holes in the circuit board, and SMD resistors are soldered to the contact tracks located on the surface of the printed circuit board (patch), which also simplifies the development and assembly of electronic devices. Due to the possibility of hinged installation of radio components, it became possible to produce printed circuit boards not only double-sided, but also multilayer, resembling a layer cake.

In industrial production, the soldering of SMD components is carried out by the following method: a special solder thermal paste (flux mixed with solder powder) is applied to the contact paths of the board, after which the robot places elements, including SMD resistors, in the right places. Details stick to the solder paste, then the board is placed in a special furnace, where it is heated to the required temperature at which the solder in the paste melts, the flux evaporates. Thus, the details fall into place. After that, the printed circuit board is removed from the oven and cooled.

For soldering components like SMD at home, you will need the following tools: tweezers, an awl, wire cutters, a magnifying glass, a syringe with a thick needle, a soldering iron with a thin tip, a hot air soldering station. Consumables require solder, liquid flux. It is, of course, advisable to use a soldering station, but if you do not have one, you can get by with a soldering iron. When soldering, the main thing is to prevent overheating of the elements and the printed circuit board. In order for the elements not to move and not stick to the tip of the soldering iron, they should be pressed to the board with a needle.

SMD resistors are presented in a fairly wide range of nominal values: from one ohm to thirty megaohm. The temperature mode of operation of such resistors ranges from -550 ° C to + 1250 ° C. The power of SMD resistors reaches 1 W. With an increase in power, the overall dimensions increase . For example, SMD resistors with a power of 0.05 W have overall dimensions of 0.6 * 0.3 * 0.23 mm, and with a power of 1 W - 6.35 * 3.2 * 0.55 mm.

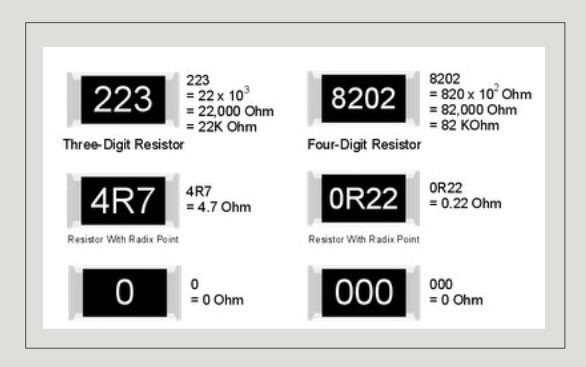

There are three types of marking of such resistors: with three digits, with four digits and with three characters:

- The first two digits indicate the value of the resistor in ohms, and the last - the number of zeros. For example, the marking on resistor 102 means 1000 ohms or 1 kOhm.

- The first three digits on the resistor indicate the value in Ω, and the last indicates the number of zeros. For example, marking on resistor 5302 means 53 kOhm.

- The first two characters on the resistor indicate the value in Ω, taken from the table above, and the last character indicates the value of the multiplier: S = 10-2; R is 10-1; B = 10; C = 102; D = 103; E = 104; F = 105. For example, marking on a resistor 11C means 12.7 kOhm.