The braking system of both cars and trucks consists of many nodes. One of the important components is the brake force regulator. Not all motorists know how this element works and works. But if it is faulty, an unpleasant surprise can occur for the driver during emergency braking. Car owners call this component of the brake system a "sorcerer." This node received such a name because its work was very mysterious and unpredictable. Let's try to understand the device, the principle of operation and adjustment of this regulator.

The main task of regulators and physics of braking

The adhesion force of the car wheel to the road surface, as well as the friction force, is proportional to the vertical loads. The coefficient of proportionality is the coefficient of tire grip.

This value does not depend on a person in any way. It can be determined based on the condition of the road and car tires. The higher the grip of the wheel with asphalt during braking, the smaller the

braking distance. And since inertia also acts during the operation of the brake pads, the redistribution of the vertical load on the wheels occurs. Therefore, the force on the disk should be uneven. The brake force regulator is also used to increase efficiency when braking when the machine is not loaded. In this case, the traction will be completely different than in the case of a loaded car.

Where is the braking force regulator on the VAZ

On many domestic cars, the "sorcerer" is located in the rear of the body. It should be noted that the brake force regulator (including VAZ 2170) is not installed on those models that are equipped with an ABS system. If we consider the modern production models of AvtoVAZ, namely, “Prioru”, “Grant” and “Kalina”, then on them the regulator is located on the left side of the bottom. When it comes to old AvtoVAZ models, the brake force regulator can be found on them in the right rear part of the bottom. These are VAZ 2101-2107 cars.

How the braking force regulator works during braking

When the driver abruptly presses the pedal, the back of the body will rise, the front - on the contrary, will fall. And at this moment the braking force regulator begins its work. Once the device is working, it will immediately allow the rear wheels to begin to slow down immediately after pressing the pedal. The fact is that if the wheels on the rear axle of the car start braking at one time with the front axle, then there is a high probability of skidding.

If the wheels on the rear axle begin to reduce speed later than the front ones, then the risk of skidding is reduced to almost zero. When the car slows down, the rear distance between the bottom and the rear beam increases. As this gap grows, the lever releases the piston of the regulator and, as a result, the fluid line closes, which approaches the rear wheels. As a result, they will not be blocked, but will continue to rotate.

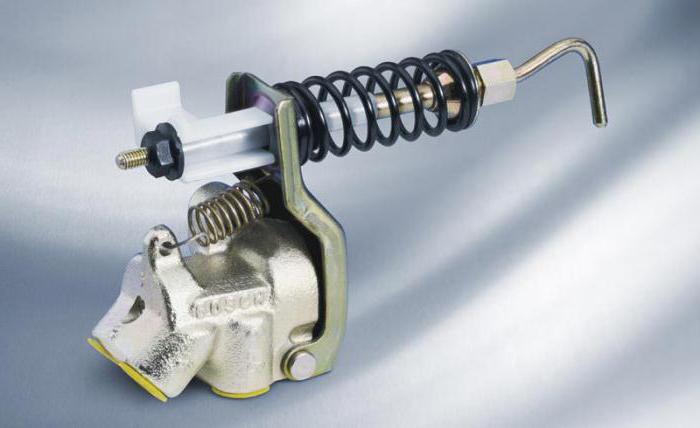

The device of the brake force regulator

It is mounted on a body bracket and is connected on passenger cars with a rear axle beam on traction and a torsion lever. The second end of the last element acts on the piston of the regulator. The input of the regulator is connected to the main brake cylinder, and the output is connected to the rear. The device is controlled by a drive connected to the rear beam. As for the design, the brake force regulator consists of a body divided into several cavities (usually two). One of them is connected to the main cylinder, the other to the rear system. There are also pistons and valves through which the brake fluid is blocked .

At the time of the start of operation, its pressure in the two chambers is the same. However, in the former, the fluid acts on a smaller portion of the piston, while in the latter, on a larger portion. The piston tends to move, but cannot do this due to the centering spring. If the pressure starts to increase in the master cylinder, then the piston can easily overcome the force of the spring, as a result of which the valve will block the fluid access. This is the classic principle of operation of the brake force regulator. Today there are hydraulic elements, pneumatic, electronically controlled.

Trucks and brake force regulator

The KamAZ car has an automatic regulator. It performs almost the same tasks as the device in passenger cars. It automatically controls and distributes the force of the pads on the wheels of the rear axle, depending on how the axial load on the wheels changes. It also helps to speed up their unlock. The action of such a regulator is based on a change in air pressure in the chambers of the system on the rear of the trailer, depending on axial loads with a decrease in speed. The KAMAZ brake force regulator is mounted on the frame.

The lever and traction through the elastic part, as well as the rod, are connected to the beam of the bridge and the rear wheel trolley in such a way that distortions and twisting during the operation of the system will not affect the braking force. An elastic element is necessary to protect the control device from various damages during the vertical displacements of the rear axles. It also significantly reduces vibration and absorbs tremors when driving on rough roads.

The regulator device on KamAZ vehicles

This assembly consists of a valve, a valve follower with an actuator. Also in the device there is a piston with an inclined rib. There is also a membrane that is in connection with the piston. Inside the case there are connecting tubes. According to the latter, air enters under the piston, due to which the smooth operation of the system is ensured when the valve is shut off. The regulator channels are attached to the top of the crane, and the second channel is connected to the brake chambers on the rear wheels. The third conclusion works with the atmosphere. When the car slows down, the air flowing from the top of the brake valve to the first channel of the regulator displaces the piston down, and on the other hand it is compressed until it stops. The valve is pressed against the seat of the pusher and the second channel at this moment is more connected with the atmosphere. Then further movement of the piston will open the valve. Air from the first channel will enter the second, and then to the brake chambers. The MAZ brake force regulator has a practically similar device and principle of operation.

Devices from Wabco

Wabco is a manufacturer of spare parts for trucks. Among the huge range of products there are parts for brake systems. In the company directory you can find everything you need to repair trucks.

One of the devices this brand manufactures is the Wabco braking force regulator. It is suitable for installation not only on trucks, but also on trailers of various models and brands. Many truck owners appreciated the quality of the equipment and spare parts from this manufacturer. The quality of the regulator is much better than the standard device. It is installed on factory mounts.

How to check the "sorcerer"

On the example of a VAZ 2110 car, you can consider how the check of the brake force regulator is performed. There are few symptoms. This is a sidetracking of the car, frequent breakdowns in a skid, insufficiently effective braking. On the VAZ 2100, the RTS is located on the left under the bottom in the area of the rear wheels. All operations with him are best carried out by lifting the car on a lift, installing on a flyover or viewing hole. Major defects of the device can be easily detected visually. If fluid leaks are observed, the cuff is most likely worn or damaged. If the regulator piston is in one position and does not want to move, then most likely it is soured. This defect can be determined by visual diagnosis.

If these problems occur, repair will not help here. Only a replacement can solve the situation. Many replace a simple regulator with a crane-regulator of brake forces. This system is considered more convenient. If the element is completely clean, there is a small gap between the drive lever and the plate, the stem moves perfectly in both directions when you press the pedal, then the mechanism is fully functional, and you do not need to do anything with it.

How to regulate RTS

If you take VAZ cars, then the adjustment of the brake force regulator greatly depends on the position of the body. The adjustment must be performed not only during each maintenance operation, but also when replacing suspension parts - springs or shock absorbers, after repair work on the rear beam and when replacing it. To configure the car must be put on the overpass. This is done not only for the convenience of work, but also for installing the suspension in an equilibrium position. In this state, when you press on the trunk with your hands, the car will swing two to three times. So, to set up, you first need to loosen the fasteners to the bracket. It is necessary to achieve a gap of 2 mm between the elastic plate, in which the rod abuts and the lever. This is done by moving the mechanism.

It must be borne in mind that in the process it is necessary to overcome the resistance of the spring. They are quite large, so it is recommended to use a special tool or other suitable device. Then the bolts are tightened and the gaps are checked using a feeler gauge. If there is no such tool, then you can use a drill with a diameter of 2 mm or a suitable coin.

Sea trials

About whether the adjustment is well made, you can understand only on the go. It should accelerate to 40 km / h, and then press the pedal, and during braking to evaluate how the car behaves. You should not be “thrown” forward. With high-quality adjustment, both parts of the car roll minimally.