A thermoelectric generator (TEG thermogenerator) is an electrical device that uses the effects of Seebeck, Thomson and Peltier to generate electricity through thermo-emf. The effect of thermo-EMF was discovered by German scientist Thomas Johann Seebeck (Seebeck effect) in 1821. In 1851, William Thomson (later Lord Kelvin) continued thermodynamic research and proved that the temperature difference is the source of electromotive force (EMF).

In 1834, the French inventor and watchmaker Jean Charles Peltier discovered the second thermoelectric effect, found that the temperature difference occurs at the junction of two different types of materials under the influence of electric current (Peltier effect). In particular, he predicted that EMF occurs inside a single conductor when a temperature drop is present.

In 1950, Russian academician and researcher Abram Ioffe discovered the thermoelectric properties of semiconductors. The thermoelectric power generator began to be used in autonomous power supply systems in inaccessible areas. The study of outer space, the exit of man into space gave a powerful impetus to the rapid development of thermoelectric converters.

A radioisotope energy source was first installed on spacecraft and orbital stations. They are beginning to be used in a large oil and gas industry for corrosion protection of gas pipelines, in research work in the Far North, in the field of medicine as pacemakers, in the housing sector as autonomous sources of electricity.

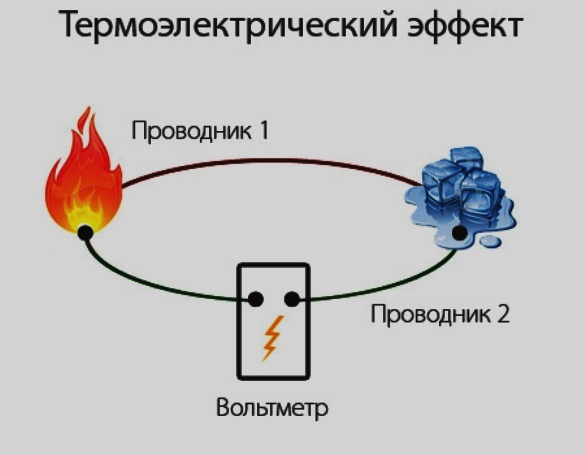

Thermoelectric effect and heat transfer in electronic systems

Thermoelectric generators, the principle of which is based on the integrated use of the effect of three scientists (Seebeck, Thomson, Peltier), received their development almost 150 years after discoveries, much ahead of their time.

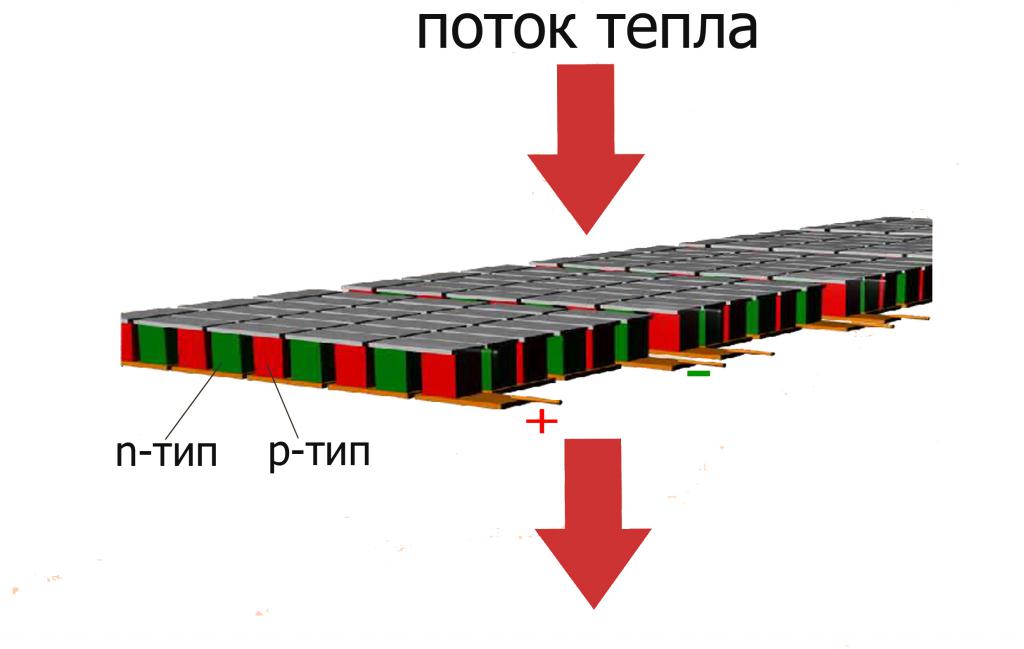

The thermoelectric effect is as follows. For cooling or generating electricity, a “module” is used consisting of electrically coupled pairs. Each pair consists of a semiconductor material p (S> 0) and n (S <0). These two materials are connected by a conductor, the thermoelectric power of which is considered equal to zero. Two branches (p and n) and all other pairs that make up the module are connected in series in an electrical circuit and in parallel in a thermal circuit. A TEG (thermoelectric generator) with such an arrangement creates the conditions to optimize the heat flux that passes through the module, overcoming its electrical resistance. An electric current acts in such a way that charge carriers (electrons and holes) move from a cold source to a hot source (in the thermodynamic sense) in two branches of a pair. At the same time, they contribute to the transfer of entropy from a cold source to a hot one, to a heat flux that will withstand heat conduction.

If the selected materials have good thermoelectric properties, this heat flux created by the movement of charge carriers will be more thermal conductivity. Therefore, the system will transfer heat from a cold source to a hot one and will act as a refrigerator. In the case of electricity generation, the heat flux causes a displacement of the charge carriers and the appearance of an electric current. The larger the temperature difference, the more electricity can be obtained.

TEG Efficiency

Estimated by efficiency. The power of a thermoelectric generator depends on two critical factors:

- The volume of heat flux that can successfully move through the module (heat flux).

- Temperature Delta (DT) - The temperature difference between the hot and cold side of the generator. The larger the delta, the more efficient it works, so conditions must be provided constructively for both maximum cold supply and maximum heat removal from the generator walls.

The term "thermoelectric generator efficiency" is similar to the term applied to all other types of heat engines. So far, it is very low and amounts to no more than 17% Carnot efficiency. The efficiency of the TEG generator is limited by the Carnot efficiency and in practice reaches only a few percent (2-6%) even at high temperatures. This is due to the low thermal conductivity in semiconductor materials, which does not contribute to the efficient generation of electricity. Thus, materials with low thermal conductivity, but at the same time with the highest possible electrical conductivity, are needed.

Semiconductors are better at this task than metals, but are still very far from those indicators that would bring the thermoelectric generator to the level of industrial production (with at least 15% using high-temperature heat). A further increase in the efficiency of TEG depends on the properties of thermoelectric materials (thermoelectrics), the search for which the entire scientific potential of the planet is currently occupied.

The development of new thermoelectrics is relatively complex and costly, but if successful, they will cause a technological revolution in generation systems.

Thermoelectric materials

Thermoelectrics consist of special alloys or semiconductor compounds. Recently, electrically conductive polymers have been used for thermoelectric properties.

Thermoelectric Requirements:

- high efficiency, which is due to low thermal conductivity and high electrical conductivity, high Seebeck coefficient;

- resistance to high temperatures and thermomechanical influences;

- accessibility and environmental safety;

- resistance to vibrations and sudden changes in temperature;

- long-term stability and low cost;

- automation of the manufacturing process.

At present, experiments are ongoing on the selection of optimal thermocouples, which will increase the efficiency of TEG. The thermoelectric semiconductor material is an alloy of telluride and bismuth. It was specially made to provide individual blocks or elements with different characteristics “N” and “P”.

Thermoelectric materials are most often made by directional crystallization from molten or pressed powder metallurgy. Each manufacturing method has its own particular advantage, but materials with directed growth are the most common. In addition to bismuth tellurite (Bi 2 Te 3), other thermoelectric materials exist, including alloys of lead and tellurite (PbTe), silicon and germanium (SiGe), bismuth and antimony (Bi-Sb), which can be used in specific cases. So far, bismuth and telluride thermocouples are best suited for most TEGs.

Advantages of TEG

Advantages of thermoelectric generators:

- electricity is generated in a closed one-stage scheme without the use of complex transmission systems and the use of moving parts;

- lack of working liquids and gases;

- lack of emissions of harmful substances, waste heat and noise pollution of the environment;

- device for long autonomous functioning;

- use of waste heat (secondary heat sources) in order to save energy

- work in any position of the object regardless of the operating environment: space, water, earth;

- generation of direct current at low voltage;

- immunity to short circuit;

- unlimited shelf life, 100% readiness for work.

Scopes of the thermoelectric generator

The advantages of TEG determined the development prospects and its near future:

- study of the ocean and space;

- application in small (household) alternative energy;

- the use of heat from the exhaust pipes of cars;

- in garbage recycling systems;

- in cooling and air conditioning systems;

- in heat pump systems, for instant heating of diesel engines of diesel locomotives and automobiles;

- heating and cooking in camp conditions;

- charging electronic devices and watches;

- nutrition sensory bracelets for athletes.

Peltier thermoelectric converter

The Peltier element (EP) is a thermoelectric converter operating using the Peltier effect of the same name, one of three thermoelectric effects (Seebeck and Thomson).

The Frenchman Jean-Charles Peltier connected copper and bismuth wires to each other and connected them to the battery, thus creating a pair of compounds of two dissimilar metals. When the battery was turned on, one of the transitions was heated, and the other was cooled.

Peltier-based devices are extremely reliable because they do not have moving parts, do not need maintenance, have no emissions of harmful gases, are compact and have the ability to bi-directional operation (heating and cooling) depending on the direction of the current.

Unfortunately, they are ineffective, have low efficiency, emit quite a lot of heat, which requires additional ventilation and increases the cost of the device. Such devices consume quite a lot of electricity and can cause overheating or condensation. Peltier elements with dimensions greater than 60 mm x 60 mm are practically not found.

Scope of EP

The introduction of advanced technologies in the field of production of thermoelectrics has led to a reduction in the cost of production of electric motors and the expansion of market availability.

Today, EP is widely used:

- in portable coolers, for cooling small appliances and electronic components;

- in dehumidifiers to extract water from the air;

- in spacecraft to balance the effects of direct sunlight on one side of the ship, dissipating heat on the other side;

- for cooling photonic detectors of astronomical telescopes and high-quality digital cameras to minimize observation errors due to overheating;

- for cooling computer components.

Recently, it has received widespread use for domestic purposes:

- in cooler devices powered via a USB port for cooling or heating drinks;

- in the form of an additional cooling stage for compression refrigerators with a decrease in temperature to -80 degrees for single-stage cooling and to -120 for two-stage;

- in cars to create autonomous refrigerators or heaters.

China has launched the production of Peltier elements of modifications TEC1-12705, TEC1-12706, TEC1-12715 with a cost of up to 7 euros, which can provide up to 200 W power according to the "heat-cold" schemes, with a service life of up to 200,000 hours, operating in the temperature zone from - 30 to 138 degrees Celsius.

RTG Nuclear Batteries

A radioisotope thermoelectric generator (RTG) is a device that uses thermocouples to convert heat released during the decay of a radioactive material into electricity. This generator has no moving parts. The RTG was used as an energy source on satellites, spacecraft, and distant objects of lighthouses built by the USSR for the Arctic Circle.

RTGs are generally the most preferred energy source for devices that require several hundred watts of power. In fuel cells, batteries or generators installed in places where solar cells are inefficient. A radioisotope thermoelectric generator requires strict precautions for the handling of radioisotopes for a long time after its end of life.

In Russia, there are about 1,000 RTGs that were mainly used for long-range power sources: beacons, radio beacons, and other special radio equipment. The first space RTG on polonium-210 was Lemon-1 in 1962, then Orion-1 with a power of 20 watts. The latest modification was installed on the Strela-1 and Cosmos-84/90 satellites. Lunokhods -1.2 and Mars-96 used RTGs in heating systems.

DIY thermoelectric generator

Such complex processes that take place in the TEG do not stop the local "kulibins" in the desire to join the global scientific and technical process for the creation of TEG. The use of home-made TEG has been used for a long time. During World War II, partisans made a universal thermoelectric generator. He generated an electric current to charge the radio.

With the advent of Peltier elements on the market at affordable prices for the consumer, it is possible to make a TEG yourself by following the steps below.

- Purchase two radiators in an IT store and apply thermal grease. The latter will facilitate the connection of the Peltier element.

- Separate radiators with any heat insulator.

- Make a hole in the insulator to accommodate the Peltier element and wires.

- Assemble the structure, and bring the heat source (candle) to one of the radiators. The longer the heating, the more current will be generated from the home thermoelectric generator.

Such a device works silently, and has a small weight. The thermoelectric generator ic2, depending on the size, can connect the charging of a mobile phone, turn on a small radio and LED lighting.

Currently, many well-known global manufacturers have begun production of various affordable gadgets with the use of TEG for motorists and travelers.

Prospects for the development of thermoelectric generation

Demand for household TEG consumption is expected to grow by 14%. Prospects for the development of thermoelectric generation were published by Market Research Future, having published the document “Global report on market research for thermoelectric generators - forecast until 2022” - market analysis, volume, share, progress, trends and forecasts. The report confirms the prospect of TEG in the utilization of automobile waste and systems for the joint production of electricity and heat for domestic and industrial facilities.

The geographically global market for thermoelectric generators has been divided into America, Europe, Asia Pacific, India and Africa. APR is considered the fastest growing segment in the field of introduction of the TEG market.

Among these regions, America, according to experts, is the main source of revenue in the global TEG market. It is expected that an increase in demand for clean energy will increase demand for it in America.

Europe will also show relatively rapid growth over the forecast period. India and China will increase consumption at a significant pace due to increased demand for vehicles, which will lead to an increase in the generator market.

Automobile companies such as Volkswagen, Ford, BMW and Volvo, in collaboration with NASA, have already begun to develop mini-TEGs for a heat recovery system and fuel economy in the car.