Today on sale are many tables made of wood. They are manufactured using standard technologies. A much more original and interesting table looks from a tree, which was assembled with your own hands. The flight of the master’s imagination is unlimited here. How to assemble a table yourself, will be discussed later.

Design features

Today on sale are many different tables made of wood. They, of course, are distinguished by their design and purpose. Their cost depends on the complexity and type of materials. So, simple children's tables can be purchased at a price of 1000 rubles. If the size is larger, the price is from 1500 rubles. and higher. A beautiful dining table from a solid array can be purchased at a price of 3500 rubles. and higher. However, none of the purchased models can be compared with a product that was assembled with their own hands.

Some owners decide on this step in order to save money on the family budget. After all, for example, for a summer residence you need not a artsy, but a simple and functional table. Its cost will be about 500 rubles. However, you can assemble a real masterpiece with your own hands. And the point here is not the price of the table. From a tree, a master who knows how to handle a tool will be able to create a designer, original interior object.

Tables can differ in complexity of execution, style, as well as the material from which they are made. Wood is easy to process. Therefore, from it you can create both the simplest and most complex design table. It can be installed in the room or in the kitchen, fitting the product as harmoniously as possible into the interior.

There are different types of tables. They differ primarily in purpose. There is a table for a summer residence, for a kitchen, for a computer. You can also make yourself other designs. It can be a coffee, children's, desk made of wood. There are many purposes for such products.

Wooden tables are distinguished by their design. They can be right or angled, oval or with right angles. You can make a table-book, sliding, folding design. If you wish, you can make any option you like. Transformer tables are especially popular.

The popularity of this material is explained by its positive qualities. So, wood is easy to process. Moreover, it is an environmentally friendly material. Wood does not emit harmful substances into the environment. At the same time, she looks very stylish and spectacular. Today, eco-style, in which natural materials fit perfectly, is in fashion. A self-made table can be installed in the country or in any room of the house. The item can be light and elegant. If you wish, you can create your own durable dining table made of solid wood. The choice of design depends on the skills and taste preferences of the master.

Recommendations of specialists

Before starting work, you need to make drawings of a table made of wood with your own hands. To do this, you need to determine what functions it will perform. Based on this, choose sizes. This will allow you to decide on the configuration of the product. There are a number of rules that you must follow when making a wooden table.

A wooden dining table must be created in accordance with the total area and stylistic design of the room. It should not be too big or small. The choice depends on the size of the room. It might be better to create a large table and install it in the living room or in the dining room specially designated for this.

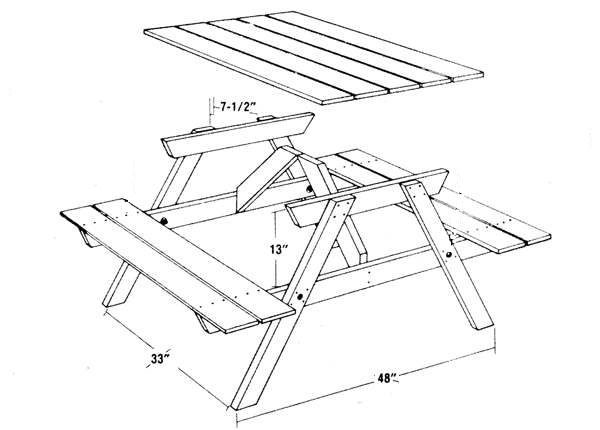

If you create a structure for the street, you need to determine how many people behind it can fit at the same time. If the table will be on the terrace, in the gazebo, take into account the dimensions of the space of construction. You can create a table that suits both several guests and a noisy big company. This design extends or transforms, creating an additional place for a comfortable location of people.

The table should be chosen by the owners at their discretion. At the same time, the features of the interior or exterior of the house are taken into account. When making a drawing of a table made of wood, you need to pay attention to the choice of the length of the structure. Each person should have at least 70 cm of table length around the perimeter.

You also need to choose the correct height of the product. It should be at least 70 cm. In this case, the height of the chairs must be taken into account. If it is planned to construct a children's table from a tree, the age of the child is taken into account. In this case, a transformer type design would be an ideal solution. If necessary, the height of the countertops can be adjusted. This allows you to operate the children's table for a long time, adjusting it to the growth of the baby.

The table must be correctly entered into the space of the room. So, if the kitchen is small, the countertop should have a size of up to 120 x 60 cm. The width of the upper canvas should be 80-110 cm.

Configuration selection

Tables and chairs made of wood can have different shapes. In some cases, choose round, streamlined shapes. In this case, the table will be oval or round. This form of countertop is often chosen. She looks spectacular. If the house has small children, the round shape of the table is less traumatic for them than the right angles of square or rectangular furniture. Some styles of interior design require the presence of clear geometric shapes. In this case, the round table will not be able to fit into the overall design.

The number of legs can also be different. The choice depends on the purpose and type of table. There are designs on one massive leg. This option is suitable for a small table. Most often, such products are installed in a small gazebo. A wooden coffee table with a round tabletop can also have only one massive leg. This technique allows you to create a certain stylistic effect. These tables are suitable for a classic interior.

If the design is made on one leg, you need to create a crosswise strapping for it. Otherwise, the load on the support will be too large. She may break. This type of design is also used to create a children's table.

You can assemble a structure that will stand on two massive legs. They are at a certain distance from each other. This option looks interesting if the shape of the countertop is elongated (oval or rectangular). Wooden tables for the kitchen can have two legs. In this case, people will not kick their feet on the supports. This is a comfortable configuration. The legs in this case are narrowed up. Below they expand, providing reliable support.

The most popular option is a four-leg construction. Such tables can be folding. Even a novice master can make such a product. Complex calculations in this case will not be required. They just make supports of the same shape and length. This will allow the countertop to maintain an ideal horizontal position. Designer wood tables of unusual shapes are most often created on four pillars.

Materials

When choosing a material for making a table, you need to give preference only to high-quality wood. Otherwise, it may become deformed during operation.

You can make a beautiful dining table made of solid wood. This material is quite expensive. However, products from it look very impressive. It is important to choose the right kind of tree. Not all of them are suitable for this purpose.

Also, to create a table, you can use a bar or edged board. In this case, the cost of manufacturing the structure will be lower than when using an array. The appearance of such a table may be different. It can be made antique or in a modern style. To do this, the material is subjected to specific processing. For example, rectangular, roughly processed items are ideal for loft style. Precise, neat wood tables can be used for classic designs. If you give the design a florid, unusual shape, it can be harmoniously fit into the modern style.

A certain decorative effect can be created if you make a table from croaker. This will make the table quite brutal. It is ideal for cottages made of wood, a country hunting lodge. If the croaker is wide, you can create an entire countertop from it. If the material is not wide, the canvas is collected from several interconnected boards.

A wood worktop for a table will look unusual and very beautiful if a cut of wood is used for these purposes . Its diameter may be different. You can create a very small coffee table or a massive design. You need to choose the right diameter of the cut. If desired, two saws are joined together. This allows you to create an elongated table, for example, for the kitchen. The cut must be sanded and varnished. This is an expensive technology. In the manufacture of this table a lot of waste is obtained.

Material Guidelines

When creating a kitchen, desk from solid wood or other types of designs, it is necessary to choose the right material. He must have a certain set of qualities. Dry wood should be purchased. Otherwise, it may become deformed.

Dense wood species are suitable for creating tables. In this case, the product will be durable, will not be afraid of changes in temperature and humidity. Soft wood species are constantly scratched and chipped. This material quickly loses its attractive appearance. In this case, restoration work will often be required.

A solid wood table will be difficult to process if the material is very hard. It will take a lot of time and effort. For such purposes, medium hard materials are more suitable.

When choosing wood, you need to consider that the most soft (and therefore inexpensive) are materials such as pine and spruce. The second option also has a large number of knots. There is a lot of resin in the pine. A wooden table made of such wood species can dry out, deform.

It is best to use oak, birch, larch and beech for these purposes. These materials are quite solid, but at the same time they can be independently processed using a power tool. The table will be durable. The texture and shades of such wood species are highly aesthetically pleasing.

Very hardwoods are yew, hornbeam, as well as acacia. They are rarely used to create a table with your own hands. Such material is processed only on special equipment in a production environment.

Preparatory work

There is a certain technique on how to make a table of wood. This will require a series of preparatory work. First you need to purchase the necessary tools. To create a table you will need a jigsaw and a saw, as well as a thickness gauge. You should prepare a hacksaw, jointer, screwdriver and milling cutter. To process the wood surface correctly and quickly, it is recommended to use a grinder with a special nozzle for wood. In the process, drills of different diameters will be required. You also need to purchase or make a clamp. Measurement and marking is carried out using a tape measure, square and pencil.

To calculate the required amount of materials, you will need to develop a detailed drawing. Every detail should be clearly thought out. The parameters and configuration of the product must meet the stylistic and functional requirements. When a detailed drawing is created, the necessary materials must be prepared. In this case, it will be possible to purchase them only the minimum necessary quantity.

You need to purchase wood, boards or timber. Other natural materials can also be used to create the table. Before starting installation, you need to treat the wood with an antiseptic. Therefore, the appropriate composition is bought in the amount necessary for the processing of all parts. Otherwise, the wood can rot, bugs can destroy it. Tables made of natural wood must be pre-treated. This is especially important for structures that will stand on the street.

You should also purchase sandpaper with a different fraction size. To give the wood the desired shade, paint or stain is used. In some cases glue is required. Sometimes fix parts with screws, corners. The surface of the materials will need to be opened with several layers of varnish.

Parts manufacturing

Making wood tables necessarily begins with the construction of the drawing. This diagram should detail the sequence of actions of the wizard when assembling the structure. You can create both simple and complex, unique design. In any case, first you need to work out every detail of the drawing. Then a separate diagram of each element of the future product is created. Their exact sizes are indicated.

According to the created plan, it is necessary to make all the details of the structure. For countertops, you can use a solid array or boards. The thickness of the material should be at least 3 cm. The amount of material is chosen in accordance with the scheme.

Boards, timber or solid mass need to be treated with a high-quality planer. When the surface is smooth, polished, you can cover the wood with an antiseptic composition. The material should dry.

If the countertop is made of boards, they must be carefully sanded and folded side by side, forming a rectangle from them. Joints must be carefully aligned. Bars are applied to them from two sides. The material for fixing the boards needs to be cut according to the width of the countertop.

The beam must be screwed to the boards. To do this, in the center of each board make a recess for the bolt. It should enter the material at 2/3 of its thickness. Holes are also created in the bar. Only the top of the recess should be wide. In this case, the hat will sink in the material, it will not be visible.

It is better to round the corners of the dining table made of wood. You also need to attach a board down. It is fixed on self-tapping screws and glue. After that, the surface of the countertop can be sanded and varnished.

Glued massif for countertops

A wooden kitchen table can be created from glued wood. This technology has several advantages. The countertop will be uniform. There will be no gaps between the boards. At the same time, the material will not crack or deform. For work you need to take 4-5 boards. Their edges should be smooth.

At the ends you need to make recesses with a step of 10 cm, which should be about 9-11 mm. In the side boards of the countertops, holes are made only on one side. Boards need to be ground finely. Their side surfaces are treated with wood glue. Then dowels are inserted into the holes. Boards fasten tightly. The ends need to be aligned. Next, the countertop needs to be compressed so that the boards snug against each other. When the glue dries, you can continue to assemble the table from the tree. Do it yourself with your own hands and make legs.

Table legs

Wooden table legs are best made simple. In this case, they will be reliable and durable. You can not make drawings for the legs, if they do not have a complex configuration.

First you need to pick up 4 equal bars. Their length is selected in accordance with the height of the table. The bars are installed in the corners of a pre-prepared countertop. You need to connect them with boards around the perimeter. After that, you need to glue the legs to the countertop and leave until completely dry. To fix it more reliably, metal corners can be used for fixation.

Creating a table with your own hands from a tree, you can decorate its legs with branches of ornate shape. They are pre-varnished. This will create a beautiful coffee table. If the table is massive, you need to connect using bolts. Strengthen the effect will allow the use of adhesive. Screws need to be screwed in relation to the board at an acute angle.

Finish finish

A wooden table after assembly needs additional processing. It is necessary to properly treat the surface with varnish. The surface must first be sanded. Pay particular attention to the edges. On all surfaces you need to apply a layer of high-quality varnish. You can paint some parts or the entire table.

The surface can be coated with colored or transparent varnish. This allows you to emphasize the natural beauty of the material. Decorative decoration may be different. It involves the use of different table painting techniques. You can create beautiful compositions in accordance with the style of the interior.

Having considered the features of creating a table from a tree, you can do all the work yourself. In this case, the owners will receive an original, interesting interior item that will become a real decoration of the house.