The ability of explosives (BB) to enter into uncontrolled chemical reactions can lead to disastrous consequences. For example, a house explosion mainly occurs as a result of a gas leak. Also, the cause may be careless handling of flammable and flammable substances. The source of the explosion at home can also be a TV. On the street, after a collision and a fire caused by a fuel leak, vehicles explode. However, this explosive ability is used in mine blasting. There are pyrotechnic specialists in the engineering troops who, depending on the conditions and characteristics of the charges, undermine them in one way or another. They can use fire or electric.

According to experts, the simplest is the fire method of blasting. Moreover, it can be produced without using complex and expensive devices. You will learn more about this method and safety rules for blasting from this article.

Getting to know the way

For the firing method of blasting you need a bunch of sparks that are transmitted through a special cord. One end is inserted into the sleeve, which is used as a detonator capsule. Thus, using a flame-retardant cord, an impulse enters the sleeve, as a result of which detonation follows, followed by an explosion of explosives. They use the fire method when they want to produce multiple-time serial detonation of several charges. According to experts, they often resort to it when detonating single charges.

About the advantages of the method

Unlike the electric method or radio explosion, which requires special blasting machines, an electric network and electric detonators, only a smoldering wick, matches, an incendiary tube with a detonator capsule and a flame-retardant cord are needed for the fire one. Industrial-made tubes are already equipped with a cord with a plastic sheath ZTP. Also, this element can be made by a specialist from the engineering forces.

About the disadvantages

Despite the undeniable advantages, the fire method of blasting is not without some drawbacks. First of all, a pyrotechnician performing mine clearance is very at risk. The fact is that when the cord is ignited, he has to be near charges with explosives. The second minus is that it is not technically possible for a military engineer or civilian pyrotechnician (if mine clearance is carried out in the industrial sector) to check all the elements. But that is not all.

It may be that the incendiary tube or cord is of poor quality. In addition, it is not possible to neutralize a series of charges by the firing method. They should be located at a great distance from each other so that the explosion from one charge does not initiate others.

Types of Capsules

The incendiary tube consists of a detonator capsule, a flame-retardant cord and an ignitor (smoldering) wick. The capsule initiates (detonation) the explosive charge.

KD 8-A and KD 8-M capsule models are used. These detonators have a similar design and dimensions: 4.7 cm in length and 7 mm in diameter. They differ only in the type of explosive used for initiation, and in the case material: they are made of aluminum and copper. The input of the fireproof cord into the detonator capsule is made from the open side of the CD.

Description

The detonator capsule is presented in the form of a sleeve with an inner diameter of 6.5 mm. One end part is closed. On the other hand, a 1.02 gram blasting explosive is pressed in. Explosive must have increased power. Therefore, every military engineer uses RDX or tetryl.

In the middle, the sleeve was equipped with a pressed inverted cup made of aluminum. Inside it contains explosives. The lower layer on the side of the high-power blasting explosive is represented by lead azide (0.2 g), and teneres (0.1 g) is located on top. This element alone cannot initiate detonation, but only in tandem with lead azide. From the open end, part of the sleeve is hollow. The cup on this side is equipped with a small hole. To prevent explosives from waking up through it, a thin silk or nylon mesh is installed inside the hole. From the closed end, the sleeve is equipped with a cumulative recess, in the direction of which the pulse force is much stronger.

How to handle the capsule?

According to experts, the detonator capsule is very sensitive even to minor external influences. It can be initiated not only by a spark, but also by shock, heat and friction. In addition, an explosion can occur if the sleeve is flattened. Therefore, you should handle this item with extreme caution.

Protect the detonator capsule from falls and bumps. If explosive mercury is used to equip the liner, the detonator must not be wetted. Capsules are stored and transported in special cardboard boxes of 50 pieces each. Also for this purpose metal boxes are used in which moisture does not get. In this case, the sleeves are kept in an upright position of 100 pieces. Position them so that the dulce is turned up.

To the place where blasting is underway, detonator caps are delivered in special packages of 10 pieces or cases made of wood. Carry them in bags separate from explosives. If you adhere to safety rules, it is forbidden to carry cartridges in pockets during blasting operations.

About defective detonators

If there are through cracks or any dents on the sleeve, it is considered unsuitable for use. This also includes capsules with powdered composition for initiation of the walls. In addition, the detonators can be a solid coating or large spots. This indicates the oxidation of the sleeve body. Such a capsule is also considered defective.

About the cord

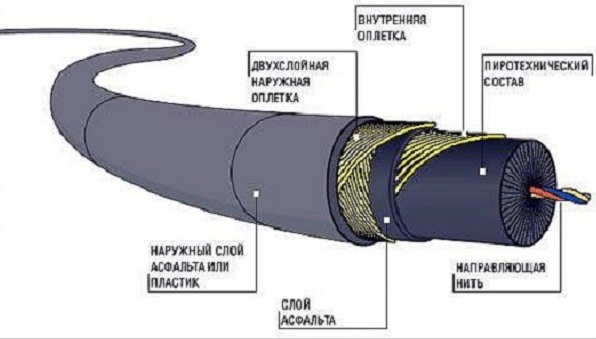

A fire-resistant cord 10 meters long is folded into a bay. This element consists of an outer shell and a powder core. The cord is marked as OSP, OSHA or OSHA. It all depends on what type of winding is used. According to experts, 600 mm. OSHP brand cord burns out in 70 seconds. It can burn both in air and under water. Much faster (50%) it burns at great depths. However, at a 5-meter depth, speed is difficult to predict. So that the powder core does not dampen when the cord is folded into the bay, both ends are impregnated or covered with wax. Today, engineer troops no longer supply such cords. The main scope of their application is civilian industry. Unlike OSP, OSHA and OSHA have an asphalt pavement, for the manufacture of which cotton or linen threads are used. The cords of these brands are gray-black.

This is due to the fact that the threads are impregnated with special mastic - tar. OSHA is not used under water and in rooms with a high level of humidity. For such cases, an OSHA with a double asphalt shell is provided, and therefore high waterproofing properties. There is also the OSHP-MG brand. Marking indicates that the flame retardant cord is slow burning. It is covered with a gray-blue plastic shell. The core is not represented by gunpowder, a multicomponent composition. Within 3 seconds, only 10 mm of length is burned. To check at what speed the cord will burn, from one end you need to cut a piece 30 mm long. and destroy. The next cut 60 mm segment is set on fire. Time is tracked using a stopwatch. If the cord suddenly fades or the burning rate is less than 60 seconds, then you can not use it.

About the ignition wick

This element is needed to ignite the cord. For its manufacture, cotton or linen threads are used. They are twisted into a cord, and then impregnated in potassium nitrate. The wick is light yellow in color and has a diameter of 6 to 8 mm. Smolders at a speed of 1 mm. per minute. Before operating the ignition wick, check its connection to the cord. The detonator capsule and the flame-retardant cord are connected by combined crimping. At the same time, they work with wire cutters and a cord, as well as screwdrivers.

About incendiary tubes

In the troops and in the industrial sphere incendiary tubes (ST) of the following grades are used:

- ZTP-50. Product with mechanical or grate igniter. It burns under water in 40 seconds and 50 in air. It is completed with a cord of white color.

- ZTP-150. Burning time under water is increased to 100 seconds (150 in air). A mechanical or grater igniter is also used.

- ZTP-300. The cord of blue color burns for one minute (300 sec. Under water).

The ignition tube, which uses a mechanical igniter, consists of the following elements:

- Detonator Capsule.

- Bushings.

- Aluminum clutch. It indicates a number that indicates in seconds the deceleration time.

- Flame retardant cord.

- Ignition unit.

- Housings.

- Drummer.

- Springs with a check.

- Rings.

The body of such a TK with two slots: deep and shallow. In the first insert the check on the fuse. In this case, it is technically impossible to pull it out of the ring. To do this, the igniter is screwed onto the tube assembly, the capsule is screwed into the charge socket, and the pin is slightly lifted and transferred to a shallow slot. The product is held in the left hand by the body, the ring pulls out the ring with the right.

As a result, the spring begins to act on the drummer, which pierces the CD. This is followed by ignition of the cord, the sparks of which initiate a charge explosion.

On the implementation of firing a fire. Start

Upon arrival at the place, the engineer first of all prepares the section of OS. The length of the cord will depend on the number of charges and the time it takes for the pyrotechnician to hide in cover. If it is necessary to carry out a series of detonations, then the time to initiate all TK is additionally measured. If the explosive charge is in the soil, then it will be more convenient to ignite an OSh of at least 250 mm in length. Next, with the help of a dry and sharp knife, cut the desired length of the cord at an angle of at least 45 degrees. This recommendation is due to the fact that the ignition of the powder core in the OR occurs much faster if the cut is made at the most acute angle. The second end face is cut at a right angle. Specialists use a wooden lining. So that the cut does not turn out soaked and the powder does not spill out of the core, the cut must be made with one strong pressure.

Second step

Next, you need to remove the sleeve of the detonator capsule from the pencil case. Before operation, it is carefully inspected. If any defects are found, she is sent to the marriage. It may be that specks have entered the capsule. To extract them, a CD dulcé lightly tap on the nail. Do not use items for this purpose. Otherwise, the initiation of explosive. The end of the fire-resistant cord, which is cut at a right angle, is carefully inserted into the sleeve until it stops. OS should be included in CD easily. You can’t press or rotate it, otherwise it will trigger the explosion of the capsule. If the pyrotechnician felt that the cord in the sleeve is too loose, then its end is wrapped with insulating tape or paper. Then, by crimping, the CD and the fire-resistant cord are fixed. At the same time, the OS is held in the left hand, holding the capsule with the index finger.

Put a crimp with your right hand. It is desirable that its lower part be flush with the CD cut or the capsule cut protrudes 0.2 cm. The incendiary tube is crimped in two ways. After each crimp, you can loosen the crimp and rotate the TK, or you can hold it motionless, working crimping around its axis. This procedure is considered to be performed correctly if a smooth annular neck is formed on the CD. This indicates a strong connection of the flame-retardant cord and the detonator capsule.

Finally

It is forbidden to engage in the manufacture of incendiary tubes in the vicinity of places where explosive materials are stored and distributed. Cords, detonator caps and ignition tubes cannot be laid on the ground even in dry weather. If it is raining or snowing, it is only allowed to make a sunshade with a raincoat or tent. Often several explosive specialists have to work simultaneously. A 5-meter distance must be observed between them.