The knife has been used by man for several thousand years. It is difficult to imagine life without this product, which has become an indispensable assistant. In the modern knife market, you can get a variety of patterns of pricking and cutting products. In the structure of the knife there are elements around the names of which there are disputes today. The reason for this is the definitions used to designate many parts and details in blades and handles, borrowed from other languages. However, according to experts, there are certain terms that are found most often in technical documentation. Information on the structure of the knife and a description of all the elements can be found in this article.

Introducing the cutting tool

The knife is a specially treated metal strip. The main element in the structure of the knife is the blade. This part can have any section and be flat, multifaceted and round. Multifaceted blades are in the form of a rhombus and a triangle. The choice of form depends on the purpose for which the knife is intended, since such a blade can cause a wide variety of injuries. Nevertheless, you should not consider the knife as an exceptionally cold weapon. It is considered a universal tool that will come in handy when solving quite peaceful tasks.

About design

In the structure of the knife, two parts are distinguished: the blade and the handle. In steel blanks, in addition to the blade of any shape and size, there is a shank, through which the knife is equipped with a handle. Experts have developed many methods for mounting the handle to a steel billet. The mounting method becomes decisive for the shape of the shank and its name.

About the blades. Description

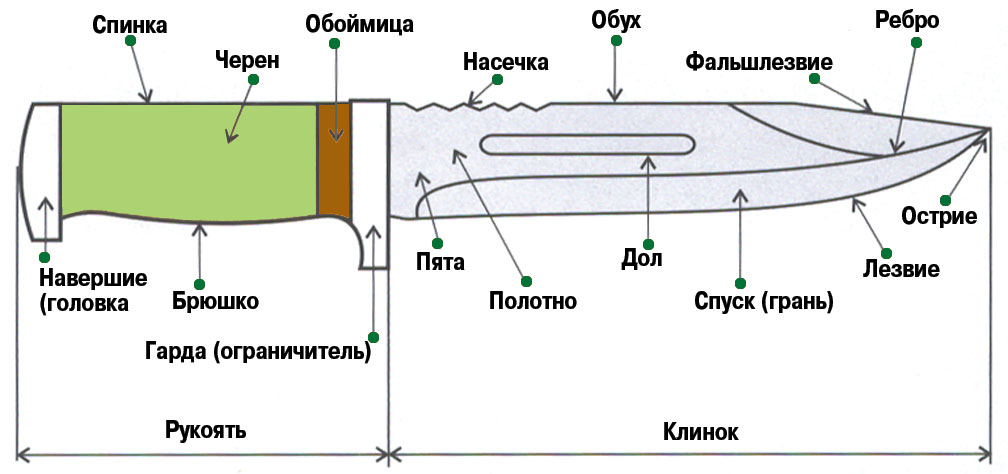

In the structure of the knife, any blade is represented by the following elements:

- Plane or golomennom. This is the thickest part of the blade.

- With a blade. It is a working cutting sharpened edge that stretches from the heel to the tip. Some consumers, far from knife-making, the term “blade” is applied to the entire working part of the blade inclusive with the heel.

- By carts. Through these two narrowest surfaces, a cutting edge is formed. These elements are formed during sharpening, when a blade is created under the influence of a sharpener.

- Fifth or fifth. It is a non-sharpened area and a continuation of the blade. The task of the heel is to increase the rigidity of the knife and prevent the handle from interfering with the sharpening of the blade. In the structure of the knife, a working part is formed from the heel and blade.

- Butt. Represents the part opposite to the cutting edge. Butt sharpening is not subject. According to experts, it is not necessary that this element be direct. It can take many forms.

- Bevel. The term is applicable to a bend or beveled part of a butt. In order to improve the external effectiveness of the knife, bevels are often sharpened. Due to the fact that this sharpening does not have the necessary sharpness at all, and therefore does not improve the functionality of the knife, the bevel is often called false blade.

- The rise. It is a bend in the blade. Directed towards the axis of the knife.

- The edge. In this part, the lift and bevel or butt are connected to the cutting edge. Depending on the location relative to the butt, the tip can be “soaring” and “falling”. In the first case, the tip over the butt, in the second - below its line. In table knives, a smooth rounding of the butt to the cutting edge is observed, and the point of the tip is absent.

- The descent. It is the narrowing of the surface of the knife to the edge. Slopes come in many different forms with their own merits. The most common form formed by milling is considered lenticular. With such a profile, a knife blade with a thick butt portion is the thinnest. For this reason, it is also called shaving. Judging by numerous reviews, most knife makers equip their products with lenticular slopes. High popularity is due to the fact that the knife is obtained with a much reduced weight, without losing its rigidity.

- Dolom. This term is called a recess on the surface of the blade. Thanks to the blade, the knife has a reduced weight and improved rigidity.

- Rib. This element is in the form of a line, which is formed by golomen and descents. Due to the fact that the planes in the blades can be narrowed closer to the butt, the ribs are considered the thickest parts in the structure of the knife. Photos of cutting products - later in the article.

Many manufacturers by chemical or laser engraving brand their products, that is, they put a mark on which you can find out about the grade of steel used and the method of its primary processing. According to experts, gilding, blackening and other technological methods are used to apply a factory article on a knife.

About the handle

This element is considered very important in the structure of the knife, as it allows you to perform its reliable retention during operation. Knife shanks are made according to the type of future handle.

They are typesetting, overhead or plate and riders. Overhead handles are represented by two plates of various materials that are mounted on the shank with riveting. Riders are attached in two ways:

- Rider. In a strong material (wood or bone), a hole is drilled into which, by applying force, a shank is inserted. Hence the name of the handle. The mounting location is additionally fixed with glue or resin.

- Cross-cutting. Before fitting, the thread is preliminarily made in the material, onto which all components of the handle are tightened with a nut. In this case, resin or other adhesive mixtures are also used.

About the basic elements of the handles

The handle of the knife consists of the following parts:

- Cuttings. It is considered the main part, since it is the palm that touches it.

- Back. This element has the shape of a barrel. Located on top of the handle.

- Abdomen. Represents the bottom. For a specific grip method, knives with abdomen of various shapes are provided.

- Subdigital notch or radius. In the form of a hollow for the index finger. When performing a stab, a knife with a radius provides the owner with additional emphasis. There are two types of subdigital notches. The radius is mainly equipped with handles, less often the blades themselves. In the second case, the spot is the heel.

- Garda. Mostly ordinary people call the front stop in the handle. Specialists use the term "cross". The task of the guard is to prevent the hand from slipping on the cutting part of the knife. Previously, the cross was an element of the hilt and was used as a protection of the hand from oncoming blows. Knife with horseman handles is equipped with a guard. The crosspiece in the design is a separate part from the entire handle. Since it is too problematic to adapt the guard in plate cutting products, many knifemakers were forced to abandon this idea.

- Tylnik. This is the name of the back of the knife, with which the blade is removed from the incision. The backs are available in products with both riders and patch arms. In the first case, the back is a separate part, in the second it is just the back of the knife handle, which is also called the butt. In the midst of Russian hunters, backskirts are more often called heads.

- Okovka, or clip. This element is located between the handle, the cross and the back. It is presented in the form of a narrow damping and grasping gasket. It is used as an annular enclosing fuse, the purpose of which is to prevent the handle from cracking from impact or drying out. Also, the shackle can be a decorative element of the knife.

- Rivets. Used for mounting linings on the shank in the plate type handles. Rivets are made mainly from aluminum.

About balisongs

That's what they call cutting products, which are known as “butterflies” among consumers. The homeland of blades are considered to be the Philippine Islands. At the end of World War II, American soldiers began to import balisongs into the United States. Due to their simple and reliable design, butterflies have gained great popularity among bandits. It is possible to open a knife easily and quickly even with one hand.

Using such a product is convenient both right-handed and left-handed. In the structure of the butterfly knife are:

- Blade.

- Handle consisting of two halves.

- Special latch.

- Pins in the amount of two pieces.

- Two axial joints.

Two parts of the handle are equipped with special grooves in which the blade is folded. In some models, shanks are equipped with protrusions that serve as limiters.

About folding knives

The classic structure of the folding knife allows you to hide the blade in the plane of the handle. There are also models equipped with an axis of rotation of the blade perpendicular to the plane. According to experts, such warehouses look much more spectacular than classic ones, but less reliable.

Mostly in folding knives, the blade in the open position will be on the same line with the handle. Fixation of the blade is provided by special structural elements - locks. In the very first warehouse, the lock was in the form of a special ledge on the butt. By its design, the knife looked like a dangerous razor. Today, several lock options have been developed. Only three are considered to be the most common of them: back up (the knife butt is equipped with a lock), liner lock (a strip-shaped lock) and axis lock (a warehouse with an axial lock).

About Features

Most folding knives are equipped with a serrator. Translated from English, serrated means "jagged." Blades may contain sawtooth and wavy serreytornye sharpening. Folding knives often have one-sided asymmetric sharpening. This element is also called a “half-serrator”, since it occupies only a part of the cutting edge.

Folding knives also have dales. As overlays use both natural and artificial materials. Handles, or dies, folding knives can be made of wood, bone, horn, metal and plastic. Despite the reliability of the clamps used in the warehouses, in order to prevent unplanned folding, the design was equipped with special fuses.

In knives with a lock on the butt, the place for the fuse is the cutout area of the locking lever, with the linear type lock the front of the handle.

The knives are equipped with bronze, brass, nylon or fluoroplastic washers, the task of which is to prevent friction between the handle and the blade. By means of bushings and spacers, the dies are separated from each other. This creates a place for the blade.

The knife is opened by clicking on the fin or flipper. According to experts, the warehouse is sure to equip with a steel spring clip, which is also called a clip. With it, the knife is attached to the trouser belt or pocket.

About blades for tourists

In the manufacture of tourist and special sports knives use the design of storage and hunting clutchless cutting products. The base may also be a survivalist knife. However, in tourist blades to reduce their combat properties, other technical specifications are applicable.

In the structure of tourist knives there is a blade, a handle with subdigital recesses, a limiter. In some models, the back of the handle may have an additional blade and some other technical device.

About the structure of the Yakut knife

This cutting product consists of a base, for the manufacture of which soft iron is used, and a solid part - it is also a knife blade. Blade sizes can vary from 80 to 170 mm.

These knives, according to experts, are considered household. For the application of chopping and tying strikes with Yakuts, special combat ones have been developed, up to 600 mm long. The blades of Yakut knives are asymmetrical, with a straight and even butt and a very sharp cutting edge. On the right side of the holomen, they are equipped with a dol, which can stretch along the entire blade.

Some models have small grooves, also called yos. These recesses are already in the butt section, and expand towards the knife nose. Thanks to the presence of dol, the procedure for sharpening and straightening is facilitated. In addition, the blade with the dol is much thinner and sharper.

Handles for Sakha knives

In the manufacture of handles of Yakutian blades, a birch cap is used. This naturally strong wood is additionally impregnated with oils. In order to prevent the handle from turning over during operation, an ovoid shape is provided for it.