Do-it-yourself furniture is growing in popularity. Of course, you can order the manufacture of beds for individual sizes of the manufacturer. But the price in this case will be high. Therefore, it is better to make furniture yourself. And how to make a bed frame with your own hands, we will discuss in this article.

What to make a wireframe

There are many options for materials from which you can create furniture with your own hands. For a wooden frame, you need boards and bars. Those who choose this option for making a bed will be satisfied. Firstly, the simplicity of design, and secondly, low costs for boards and bars, and no less important is the enjoyment of man-made work. Most importantly, the households will appreciate, and perhaps, if there are sons, they will help the father in creating the frame.

There is such an option as creating a frame from pallets (pallet). This is also a tree, moreover, of high quality. We can say that the main advantage of the frame made of pallets is the minimum cost for maximum convenience. The bed has a modern design. How to make a bed frame from pallets will also be considered in the article.

Wooden bed

So, in order not to spend money on the bed, you can do part of the work yourself, make its frame, and buy a mattress. A self-made bed can be installed both in the country house and in the apartment. All work will require a maximum of seven days. Of course, first of all, you need to choose the design of the bed and decide on its size. The most important factor in this will be the mattress and its size.

Further, based on its parameters, proceed with the assembly of the bed frame with your own hands. Drawings of the product and specific units, prepared in advance, will allow you to decide which wood materials, how many and what sizes you need to purchase, as well as what kind of fasteners will be needed.

Blanks for bed

To begin work on creating a framework, you need to prepare:

- bed layout, with detailed elements and exposed dimensions, taking into account the size of the mattress;

- metal furniture corners for fixing the frame;

- Particleboard or wooden blanks for sidewalls and cladding;

- latoflex or boards for the bottom base;

- PVA glue;

- screws;

- wooden bolts (dowels) for connecting parts.

Usually, in the production of orthopedic bed frames, a latoflex of 53 mm and 68 mm wide is used, if you take it ready in the store. There is not much difference in how wide the latoflex or boards will be used on your base under the mattress.

Materials and Tools

To make a wooden frame, you will need the following materials, which can be ordered from a joiner or purchased on the market or in a hardware store:

- Two boards 200 x 30x 2000 mm (sidewalls of the frame).

- Three boards 200 x 30x 1400 mm (two on the head, one on the opposite side).

- On two legs a bar 50 x 50x 500 mm.

- On two legs a bar 50 x 50x 700 mm.

- Leg under the bottom of the frame 50 x 50x 300 mm.

- Three bars 50 x 30 x 2000 mm.

- 15 pcs of boards 50 x 10x 1400 mm.

From fasteners, three types of furniture corners will be needed:

- 70 x 60 mm 4 pieces;

- 35 x 30 mm 8 pieces;

- 20 x 15 mm 12 pieces.

At four corners measuring 70 x 60 mm, 2 holes for fixing the legs should be made on the inflection line. For work, you will also need 3 x 30 mm wood screws of about 100 pieces and 4.5 x 40 mm ten pieces, dowels (wooden rounded chopsticks) - 10 pieces, PVA construction glue.

To assemble the frame, you will need screwdrivers or a screwdriver, hammer, drill, ruler, tape measure, jigsaw, drill, construction stapler.

Do-it-yourself bed frame assembly

Step-by-step assembly is performed as follows:

- To make the headboard, in two prepared boards 200 x 30 x 1400 mm in size, drill holes for dowels, insert them, lubricating with PVA construction glue, connect the boards.

- The frame is assembled from the prepared back, the same board 200 x 30 x 1400 mm and two sidewalls 200 x 30 x 1400 mm, using large furniture corners 70 x 60 mm.

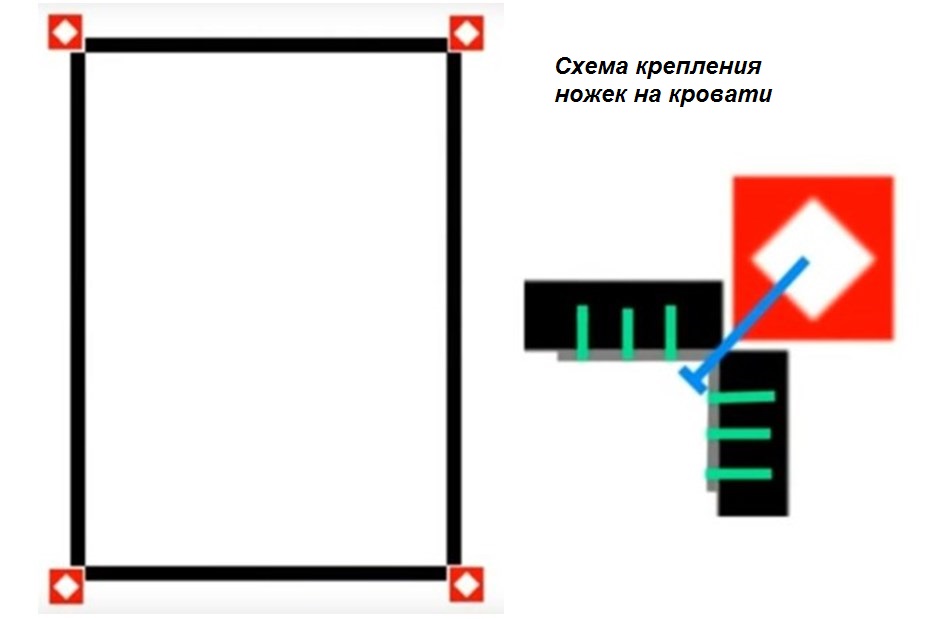

- Do it yourself to the bed frame according to the scheme in the photo above, legs are attached. Holes are drilled for dowels in the legs, the size of which is 50 x 50 x 700 mm, and to the bottom board of the head. Dowels are inserted, glued with glue and connected with wood screws.

- Two rear legs 50 x 50 x 500 mm in size are screwed in the same way.

- At the bottom of the boards of the frame, the legs are fastened with corners measuring 35 x 30 mm.

- The structure can be painted with stain and exposed with Aqua varnish.

- When the frame is assembled and varnished, you can proceed to fasten the bars 50 x 30 x 2000 mm, which will hold the mattress.

- Two bars are attached to the side boards using furniture corners 20 x 15 mm, then the middle bar and the leg are attached to it, having previously been adjusted in height.

- Unfolded evenly on the bars of the board 50 x 10 x 1400 mm, serving as the base of the bottom. They are attached to the bars with self-tapping screws.

- DIY frame is ready. It remains to put a mattress.

What is a pallet?

Consider another option how to make a bed frame. The material for its creation will serve as pallets. They can be purchased at enterprises that constantly receive bulky goods on pallets. For production, they are not returnable packaging. Sometimes, in order not to deal with their disposal, they are given away for free. You can buy euro pallets. Information on their implementation can be found on thematic Internet portals. Estimated cost ranges from 30 to 150 rubles. It all depends on the quality and appearance.

Pine and larch boards with high moisture resistance are used to manufacture the pallet. Those who made furniture from them recommend taking euro pallets, which do not require special grinding. But, before you start to make a bed frame, on a Euro pallet you need to qualitatively grind all surfaces in order to remove any roughness and clean it from dust.

Frame made of pallets

Pallets are a source of ideas for creativity. From it you can easily build a sturdy bed frame. Its advantage is the access of air for ventilation. A place to relax made in this way is an extraordinary solution, a desire to somehow stand out, to get non-standard furniture. Craftsmen who own a hacksaw and screwdriver, once tried to work with Euro pallets, were satisfied with their creations.

Pallets are best suited as frames, as well as for the original pedestal on which the mattress rises. Performing a frame of two rows of pallets, one above the other, we get a low design that resembles a bed in the dwellings of eastern peoples. If desired, it can be put on its feet using bars from pallets, getting a classic version of the bed. The back of the headboard made of a pallet can be arranged to provide a convenient shelf for a lamp, phone or book. In a bedroom in a minimalist style, the bed is the most important and only part of the interior. And made of pallets, also stylish.

Work process

What do we need for work? Joiner's tools, fixture, metal plates, corners, self-tapping screws. From the materials, pallets and a mattress themselves will be needed.

The bed area is calculated based on the size of the mattress. In this case, the bed in the photo above has dimensions along the length of 1200 + 600 = 1800 mm, the width will be 800 + 800 = 1600 mm. Good one and a half bed.

Euro pallets are assembled using metal plates, corners and wood screws. We connect two pallets using metal plates and corners. To get a bed length of 1800 mm, one pallet is not enough. We cut one of the pallets in half and add to the two pallets connected in width. On the bed frame went 3 pallets. One pallet is not enough for the headboard, so you need another (fifth) one to lengthen it by adding 400 mm.

We disassemble the remaining material from the fifth pallet and the sixth into bars and boards. The first can be used as legs for a bed, and planks make edging around the perimeter of the bed. In this case, the mattress lies in the box thus obtained.

Chipboard option

There is no universal recipe for how to make a wireframe. There are many options for its manufacture. But a few general tips to help those who decide to do this work using chipboard can be offered:

- It is necessary to take into account the relatively low strength of chipboard compared to wood. In this regard, it is recommended that the joints of individual elements be sure to duplicate with steel corners. If this is not done, the frame will quickly become unusable.

- The frame itself under the mattress should be made of metal rods or corners.

- If the design of the bed is supposed to support the floor around the entire perimeter of the side parts of the frame made of chipboard, at least they should be reinforced with ordinary boards, or metal corners.

- If a bed frame with drawers is made, the internal rigidity of the structure must be ensured by installing an internal frame made of chipboard and reinforced with metal corners.

After reading this article, even the most indecisive will understand that making a frame for any bed is not as difficult as it seems to them.