The motor speed controller is necessary for smooth acceleration and braking. Such devices have been widely used in industry. With their help, they change the speed of the conveyor belts, the rotation of the fans. 12 Volt motors are used in control systems and cars. Everyone saw the switches that change the speed of rotation of the fan of the stove in cars. This is one of the types of regulators. Only it is not intended for a smooth start. The change in rotation speed occurs in steps.

The use of frequency converters

Frequency converters are used as speed regulators for electric motors 220V and 380V. These are high-tech electronic devices that can radically change the characteristics of the current (waveform and frequency). They are based on powerful semiconductor transistors and a pulse-width modulator. All operation of the device is controlled by a unit on the microcontroller. The change in the rotor speed of the engine occurs smoothly.

Therefore, frequency converters are used in loaded mechanisms. The slower the acceleration, the less stress the conveyor or gearbox will experience. All chastotniks are equipped with several degrees of protection - current, load, voltage and others. Some models of frequency converters are powered by a single-phase voltage (220 volts), make it three-phase. This allows you to connect asynchronous motors at home without the use of complex circuits. And the power will not be lost when working with such a device.

What are regulators used for?

In the case of induction motors, speed controllers are necessary for:

- Significant energy savings . After all, not every mechanism requires a high speed of rotation of the motor - sometimes it can be reduced by 20-30%, and this will reduce energy costs by half.

- Protection mechanisms and electronic circuits . Using frequency converters, you can control temperature, pressure and many other parameters. If the engine operates as a pump drive, a pressure sensor must be installed in the tank into which it pumps air or liquid. And when the maximum value is reached, the motor will simply shut off.

- Making a soft start . There is no need to use additional electronic devices - everything can be done by changing the settings of the frequency converter.

- Lower maintenance costs . Using similar speed regulators for 220V electric motors, the risk of failure of the drive and individual mechanisms is reduced.

The scheme by which frequency converters are built is widespread in many household appliances. Something similar can be found in uninterruptible power supplies, welding machines, voltage stabilizers, power supplies for computers, laptops, phone chargers, lighting units for lighting backlight lamps of modern LCD TVs and monitors.

How rotation controllers work

You can make a do-it-yourself motor speed controller, but for this you need to study all the technical points. Structurally, several main components can be distinguished, namely:

- Electric motor

- Microcontroller control system and converter unit.

- Drive and mechanisms associated with it.

At the very beginning of work, after applying voltage to the windings, the motor rotor rotates with maximum power. It is this feature that distinguishes asynchronous machines from others. To this is added the load from the mechanism, which is set in motion. As a result, at the initial stage, power and current consumption increase to a maximum.

A lot of heat is released. Both windings and wires are overheating. Using a frequency converter will help get rid of this. If you set the soft start, then to the maximum speed (which is also regulated by the device and may not be 1500 rpm, but only 1000), the engine will not accelerate immediately, but within 10 seconds (add 100-150 revolutions every second). In this case, the load on all mechanisms and wires will decrease significantly.

Homemade Regulator

You can independently make a speed regulator for the 12V motor. To do this, you need a switch to several positions and wire resistors. With the help of the latter, the supply voltage changes (and with it the rotation frequency). Similar systems can be used for induction motors, but they are less efficient. Many years ago, mechanical regulators were widely used - based on gear drives or variators. But they were not very reliable. Electronic tools are much better than themselves. After all, they are not so bulky and allow you to fine-tune the drive.

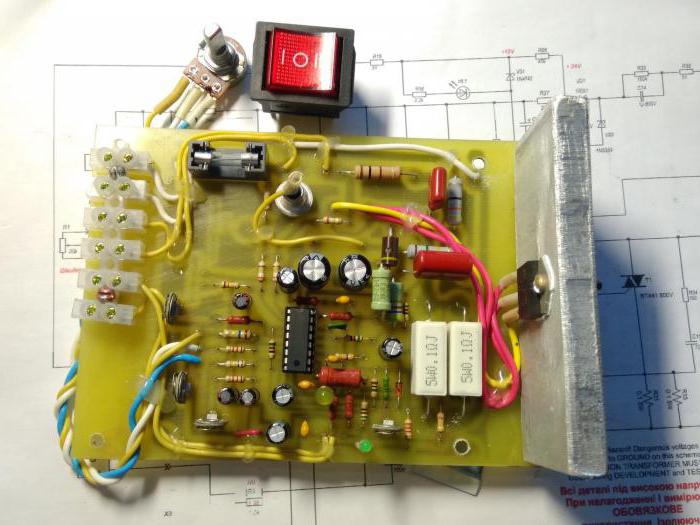

To manufacture a motor rotation controller, you will need several electronic devices, which can either be purchased in a store or removed from old inverter devices. Quite good results are shown by the VT138-600 triac in circuits of such electronic devices. To make the adjustment, you will need to include a variable resistor in the circuit. With its help, the amplitude of the signal entering the triac changes.

Management system implementation

To improve the parameters of even the simplest device, it is necessary to include microcontroller control in the circuit of the engine speed controller. To do this, you need to choose a processor with a suitable number of inputs and outputs - for connecting sensors, buttons, electronic keys. For experiments, you can use the AtMega128 microcontroller - the most popular and easy to use. In the public domain, you can find many schemes using this controller. It is not difficult to find them and apply them in practice independently. For it to work correctly, you will need to write an algorithm into it - responses to certain actions. For example, when the temperature reaches 60 degrees (measurement takes place on the radiator of the device), a power outage should occur.

Finally

If you decide not to make a device yourself, but to buy a ready-made one, then pay attention to the main parameters, such as power, type of control system, operating voltage, frequencies. It is advisable to calculate the characteristics of the mechanism in which it is planned to use an electric motor voltage regulator. And do not forget to compare with the parameters of the frequency converter.