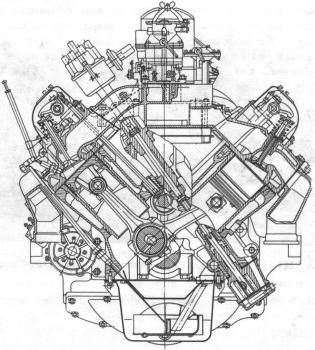

Engine ZIL 130, eight-cylinder, gasoline, internal combustion. It consists of a cast-iron block, eight pressed sleeves made of gray fine-grained cast iron, two aluminum heads with valves, a forged steel crankshaft with eight crank shafts and five support journals, which have been factory hardened to a depth of 4-6 mm, taking into account three repair sizes for decreasing when boring. All crankshaft journals are connected by channels for lubrication under pressure.

The rear of the crankshaft carries a flywheel, which is mounted on four bolts and communicates with the starter bendix. The internal bore on the crankshaft flange under the flywheel is made for mounting the gearbox drive shaft bearing. Between the flywheel flange and the cheek of the eighth crank there is a double collar for an oil seal that seals the engine oil system. At the front end of the crankshaft, three oil deflecting washers, a camshaft timing gear, two front oil deflector washers, a belt drive pulley and a ratchet are attached. When installing the

crankshaft in the cylinder block, five pairs of main liners are selected, the lower ones fit into the nests and the crankshaft is lowered from above. Then, reciprocal inserts are refilled into the covers of the main necks, after that the covers can be installed in place and bolted. The ZIL 130 engine lends itself only to manual assembly, neat and thoughtful. The pistons must be connected to the connecting rods using steel fingers, which are pressed into the piston cheeks with a slight interference fit, while passing the bronze bushing in the connecting rod head. On both sides of the piston are inserted retaining rings securing the finger.

When all eight pistons are connected to the connecting rods, it is possible to take turns from one into the cylinders and put the lower head of the connecting rod on the crank, having previously placed the liner in both the connecting rod head and the cover. On eight-cylinder engines, the principle of displacement of the connecting rod heads is applied, and the ZIL 130 engine belongs to this type of engine, so you need to be very careful about the scheme for further assembly. The slightest mistake is fraught with a breakdown of the connecting rods when starting the engine. To facilitate the passage of pistons with mounted rings into the cylinder, it is necessary to use a special mandrel, which overcomes the elasticity of the compression rings and forces them to enter the cylinder. This operation requires attention, since the lower

oil scraper ring is made of cast iron and is very fragile, it can break.

After all the pistons are in the cylinders, and the lower connecting rod heads are assembled on the crank, the bolts are tightened and locked, it is necessary to install an oil pump. It is bolted to the bottom of the unit. The pump is installed and it is now possible to mount the engine sump. This is a crucial operation, because the pallet is made of stamped steel and when landing it in place, a gasket of soft material like a cork should be laid. Of all the engines of the YaMZ plant, the ZIL 130 engine is the most highly structurally accurate, which means its assembly requires special attention. All bolts around the perimeter should be tightened evenly so that the flanging of the pallet snugly pressed at all points. After some time, tighten all bolts again.

So, the entire lower part of the engine is assembled and the next step should be the installation of a gas distribution mechanism. Since this process is very responsible, it must be performed by a qualified minder, and after assembling the camshaft, installing the rocker pushers of the valves and tightening the bolts,

valve adjustment will be required

. But before that it is necessary to install both block heads. If the head is already assembled with valves, then it sits on the asbestos-steel gasket, which is prudently laid on the cylinder block. Then the head fastening bolts are screwed in and tightened in a strictly defined order, in accordance with the assembly diagram. The tightening torque of the bolts also has its value and should not exceed it. Therefore, the tightening should be done with a torque wrench. After assembling, adjusting the valves and checking all the valve timing, it remains to cover the engine with two sealed enclosures that are tightly screwed to the

cylinder heads, closing the valve mechanisms.

The ZIL 130 car, the engine of which is assembled without violations, can work for more than one year without repair. And if one is still needed, then the technical characteristic of ZIL 130 allows the use of a number of standardized spare parts. The general data of the car engine includes: the working volume of the cylinders is 6 liters, the compression ratio is 7.5 in the new piston group, the cylinder diameter is 100 mm, the piston stroke is 95 mm, the engine weight is 490 kg, and the power is 150 hp.