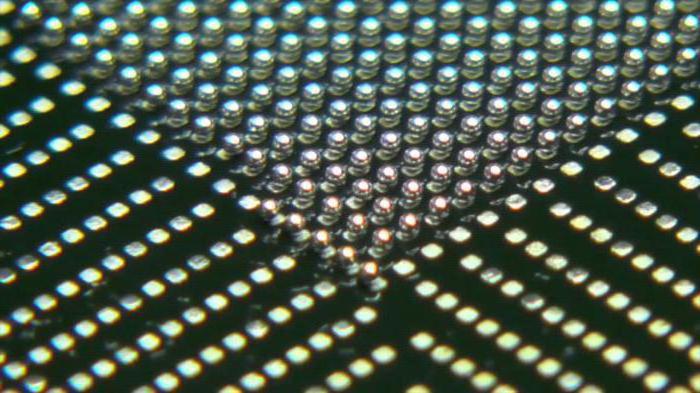

In modern electronics, there is a steady tendency for the installation to become more and more compact. The consequence of this was the emergence of BGA cases. The soldering of these structures at home will be considered by us in the framework of this article.

general information

Initially, many pins were placed under the body of the chip. Thanks to this, they were located in a small area. This saves time and creates increasingly smaller devices. But the presence of such an approach in manufacturing turns into inconvenience during the repair of electronic equipment in the BGA package. In this case, the soldering should be as accurate as possible and performed exactly according to technology.

What do you need for work?

Need to stock up:

- Soldering station where there is a hot air gun.

- Tweezers.

- Solder paste.

- Electrical tape.

- Braid to remove solder.

- Flux (preferably pine).

- A stencil (to apply solder paste to the chip) or a spatula (but it is better to stay on the first option).

Soldering BGA packages is not difficult. But for it to be successfully implemented, it is necessary to prepare the work area. Also, for the possibility of repeating the actions described in the article, it is necessary to talk about the features. Then the technology of soldering microcircuits in the BGA package will not be difficult (with an understanding of the process).

Features

Telling what the technology of soldering BGA cases is, it is necessary to note the conditions for the possibility of full repetition. So, Chinese-made stencils were used. Their feature is that here several chips are assembled on one large workpiece. Due to this, when heated, the stencil begins to bend. The large size of the panel leads to the fact that it takes away a significant amount of heat when heated (that is, a radiator effect occurs). Because of this, more time is required to warm up the chip (which negatively affects its performance). Also, such stencils are made using chemical etching. Therefore, the paste is not applied as easily as on samples made by laser cutting. Well, if there will be thermal seams. This will prevent the stencils from bending while they are being heated. And finally, it should be noted that products manufactured using laser cutting provide high accuracy (the deviation does not exceed 5 microns). And thanks to this, you can simply and conveniently use the design for its intended purpose. This concludes the introduction, and we will study what the technology for soldering BGA cases at home is.

Training

Before you start to solder the microcircuit, you need to apply strokes along the edge of its case. This must be done in the absence of silk screen printing, which indicates the position of the electronic component. This must be done in order to facilitate the subsequent installation of the chip back onto the board. The hair dryer should generate air with a heat of 320-350 degrees Celsius. At the same time, the air speed should be minimal (otherwise it will be necessary to solder a trifle placed nearby). The hairdryer should be held so that it is perpendicular to the circuit board. We warm it in this way for about a minute. Moreover, the air should not be directed to the center, but along the perimeter (edges) of the board. This is necessary in order to avoid overheating of the crystal. Memory is especially sensitive to this. Then you should pry the chip by one edge and raise it above the board. In this case, one should not try to tear with all his might. After all, if the solder was not completely melted, then there is a risk of tearing the tracks. Sometimes when applying the flux and heating it, the solder will begin to collect in balls. Their size will be uneven in this case. And the soldering of chips in the BGA package will fail.

Cleaning

We apply alcohol rosin, we warm it and we get the collected garbage. At the same time, note that such a mechanism can in no way be used when working with soldering. This is due to the low specific coefficient. Then you should wash the area of work, and there will be a good place. Then you should examine the status of the findings and evaluate whether it will be possible to install them in the old place. If the answer is no, they should be replaced. Therefore, you should clean the boards and microcircuits from the old solder. There is also the possibility that the nickel on the board will be torn off (when using the braid). In this case, a simple soldering iron can help well. Although some people use braid and hair dryer together. When making manipulations, the integrity of the solder mask should be monitored. If it is damaged, then the solder spreads along the paths. And then BGA-soldering will fail.

Knurling new balls

Already prepared blanks can be used. In this case, they simply need to be laid out on the contact pads and melted. But this is suitable only with a small number of conclusions (can you imagine a chip with 250 “legs”?). Therefore, screen technology is used as an easier method. Thanks to her, work is carried out faster and with the same quality. Important here is the use of high-quality solder paste. It will immediately turn into a shiny smooth ball. A poor-quality specimen will fall apart into a large number of small round “fragments”. And in this case, it’s not even a fact that heating to 400 degrees Celsius and mixing with flux can help. For convenience, the chip is fixed in a stencil. Then, using a spatula, solder paste is applied (although you can also use your finger). Then, supporting the stencil with tweezers, it is necessary to melt the paste. The temperature of the hair dryer should not exceed 300 degrees Celsius. In this case, the device itself should be perpendicular to the paste. The stencil should be maintained until the solder solidifies completely. After that, you can remove the fastening insulating tape and a hairdryer that will heat the air to 150 degrees Celsius, gently heat it until the flux begins to melt. After that, you can disconnect the chip from the stencil. The final result will be smooth balls. The microcircuit is completely ready to install it on the board. As you can see, soldering BGA-cases is not difficult at home.

Fasteners

It was previously recommended to do the finishing touches. If this advice was not taken into account, then positioning should be performed as follows:

- Flip the chip so that it is pins up.

- Attach the edge to the nickels so that they coincide with the balls.

- We fix where the edges of the microcircuit should be (for this, you can apply small scratches with a needle).

- First we fix one side, then perpendicular to it. Thus, two scratches will suffice.

- We put the microcircuit according to the notation and try to catch the balls with the balls to the touch at maximum height.

- Warm up the work area until the solder is in the molten state. If the previous paragraphs were executed accurately, then the microcircuit should easily fall into place. The strength of the surface tension, which the solder possesses , will help her in this. In this case, it is necessary to apply quite a bit of flux.

Conclusion

This is all called “BGA chip soldering technology”. It should be noted that not a soldering iron familiar to most hams is used here, but a hairdryer. But, despite this, BGA soldering shows a good result. Therefore, they continue to use it and do it very successfully. Although the new has always scared many away, with practical experience this technology has become a familiar tool.